Extra -Tighter Interlocks- So Easy- Fast Electrical

Many installers and DIYers choose our UX 2.0 flat panel for their basement and frame wall projects. It’s a perfect product for the application and it has all the right features in just the right amounts: R-8.5 continuous insulation, rot-resistant framing, drainage channels, electrical raceways and a simple, stackable interlocking design. The UX flat panels are designed to be the most cost-effective solution for base-level code requirements and continual comfort.

That’s great, but what if you need a solution that goes beyond base-level? Perhaps you need something that offers a little more flexibility in the future. Something that still has all the great benefits of the UX flat panel but exceeds some of those minimum requirements. Please direct your attention to the InSoFast EX 2.5 flat panel.

EX flat panels are designed to weather the rigors of an exterior application. They are built thicker, tougher and tighter and the naming scheme is no accident. Think exterior application, but don’t leave out exceeds code, extreme conditions, extra insulation. Here are some excellent reasons our outside panel can help you to save on the inside.

1. Extra Insulation

Simply put, EX 2.5 flat panels have more insulation. With a mere ½ inch of added thickness, they gain 20% more insulation than UX 2.0 flat panels. This is great if you live in a climate where the local police issue arrest warrants for Disney characters or if the words Polar Vortex and Siberian Express are part of the dialect. It’s also great for future-proofing the value of your home. Codes are always changing, always improving. Why not stay ahead of the curve.

Staying ahead may be especially important if you have a home built after 2009. Inquire with local officials about of your regional R-Value requirements. While building codes vary by region, we have found that new construction needs the insulation to meet R-10 in the material alone.

The UX 2.5 flat panel can exceed an R-10 requirement, but only when used as part of a complete wall assembly. All together, UX walls generally achieve a minimum of R-11.08 and, due to their design, actually outperform traditional wood-framed R-13 walls. The benefit of EX 2.5 flat panels is that the material starts at a continuous R-10 and can easily beat out a wood-framed R-15.

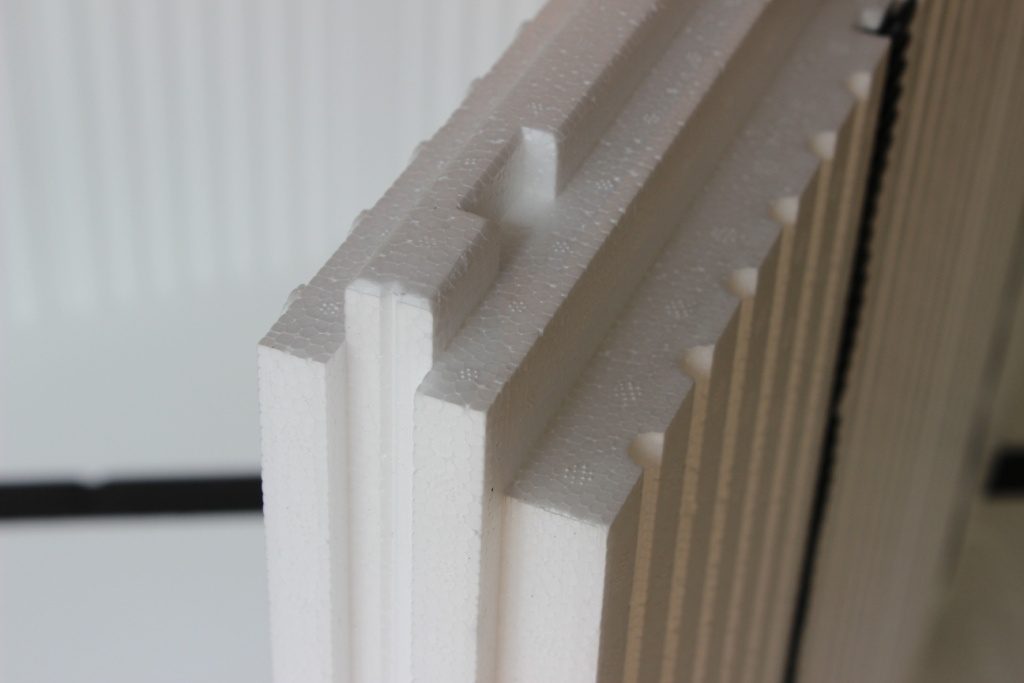

2. Tighter Interlocks and recessed studs are clearly marked on the panels

In some cases, it’s possible to install a UX flat wall too fast this is not a problem if you are using fasteners. The PL Premium adhesive has about a 30-45 minute open time before it starts to cure and the final set begins. At this time it is important not to move the panels or you could compromise the bond strength. We sometimes recommend bracing lower panels against the wall so that higher panels do not push them out. The bottom line is that EX flat panel is tighter.

The tightness of EX contributes two primary benefits. The first is a more effective continuous insulation. Remember the age-old days of taping seams? We don’t and we’re not really sure what R-value that millimeter of material was supposed to provide either. The second benefit is structural self-leveling. Tighter interlocks work like the temporary bracing we mentioned above. They keep the EX barrier truer and straighter, enabling it to bridge over cups, bows and other irregularities in the concrete wall.

Need some convincing? Watch the video below.

3. Working Around Windows is Easier

Does your basement have a lot of windows? Do you want to avoid extra steps in your installation process? We always recommend adding a solid frame around windows, doors and others openings before installing InSoFast. This ensures you will have something at these edges to attach drywall or other finishes just in case the InSoFast studs don’t line up there.

At a thickness of 2½ inches, EX panels are a perfect match for standard 2×3 lumber. Your attachment surface will be perfectly flush. If you install ½-inch drywall, everything will lay evenly at 3 simple inches. Who doesn’t love easy math?

In the picture above you can tell that the window is being prepped for UX 2.0 flat panel. The customer attached an additional ½ inch of plywood on top of a 2×4 in order to meet the 2-inch depth. Depending on your skill level and time-frame, avoiding this extra step could save you a headache, you can just use a regular 2×3 chopped to fit.

4. Deeper Electrical Boxes

Too many wires in too small a box? That’s an avoidable safety hazard. With the extra thickness on the EX panel, you’ll have room for deeper E-BOX, including those shallow masonry boxes.

This comes back to the idea of future-proofing your investment. Do you believe we live a world where our electrical dependency will slowly cap off? Researchers have found that while our society continues to make lighting cheaper via new technologies like LEDs, we never save any of that money. We simply add more lighting than we had before.

Take note of the electrical specs for your basement. With a ½-inch of drywall, you can install boxes as deep as 3 inches. You’ll avoid some potential safety hazards, make your electrician happy, and give yourself some room to expand.

In conclusion, it’s really difficult for us to say our UX flat panel is not easy. Likewise, it’s really difficult for us to say our EX 2.5 flat panel is not cost-effective. In fact, those are both ridiculously laughable ideas. HA! But there are certain benefits you can reap from choosing one over the other. Make the decision that’s best for you.

If you have any questions about the EX 2.5 panel, feel free to call us at 888-501-7899 or contact us by email.