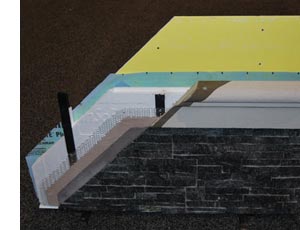

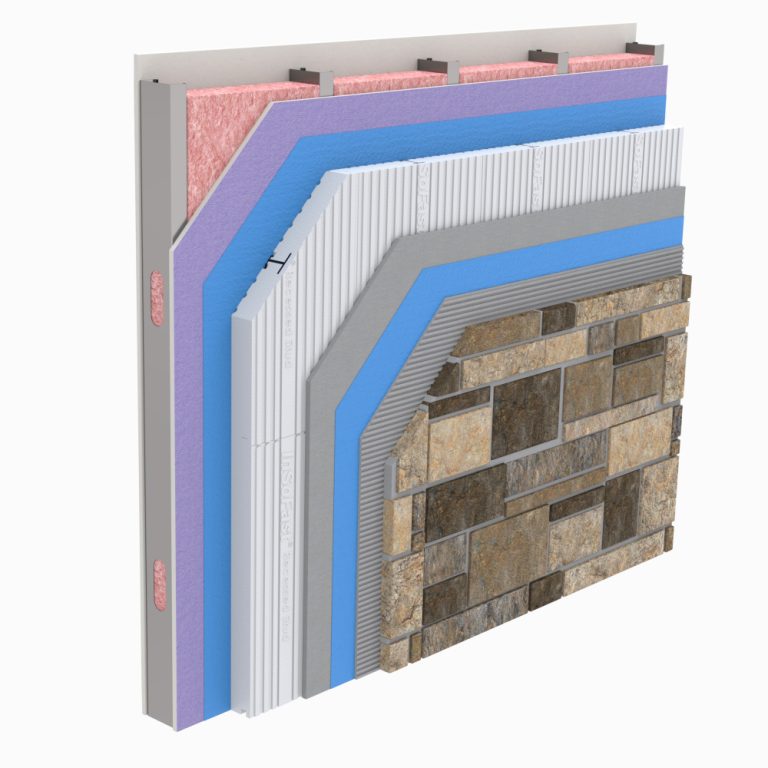

InSoFast panels are ideally suited as a drain and dry insulation board for use under traditional stucco and thin-veneer stone applications. The panels utilize tongue and groove edges to provide a smooth continuous insulation substrate and include built-in studs for lath attachment. The InSoFast panel has drainage channels which are flashed to drain bulk water.

|

|

| This is a one step process and it is ready for finishes. | Compare it to the awkward multi-step-parts and pieces process that may span over different trades. Why work this Hard? |

Flashing, Weather Resistive Barriers, and Concrete Sealers

It is important to properly flash and seal all penetrations through the InSoFast panels. See stucco manufacturer’s specifications and details which supersede the generic InSoFast details.

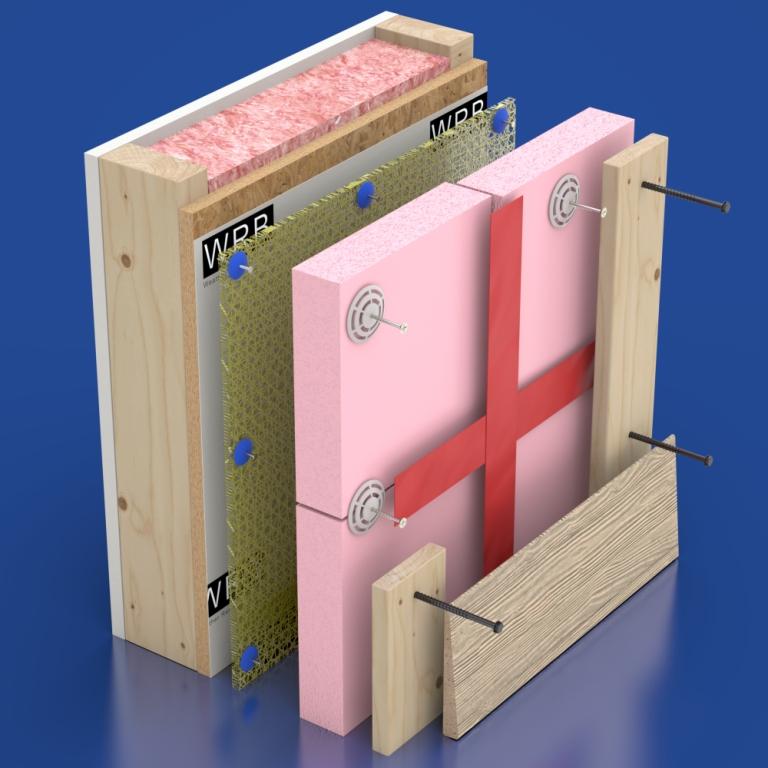

For wood or steel framed structures, InSoFast panels must be installed over sheathing with a weather resistive barrier. The weather resistive barrier must be properly sealed and flashed so that bulk water can move down the drainage channels of the InSoFast panels and exit out weep screed or drains at openings, penetrations, and bottom of the wall.

For concrete or masonry CMU walls, follow local building codes and stucco manufacturer’s instructions for proper flashing and sealants. Make sure to properly manage bulk water from the drainage channels into weep screeds or drains at openings, penetrations, and bottom of the wall.

Lath Attachment

Attach lath to InSoFast studs using #6 to #8 sharp-point, coarse thread screws.

EX 2.5 panels are 2 feet x 4 feet (610 mm x 1220 mm) and 2.5 inches (63.4 mm) in thickness. The panels are interlocking and incorporate a series of drainage channels on the back side, horizontal wiring/utility chases, and vertical wiring/utility chases. The EPS is formed with a nominal density of 1.25pcf (20 kg/m3) in accordance with ASTM C578, Type VIII. The panel has molded-in attachment studs, spaced at 16 inches on center, that are used for fastening to substrates and attaching finished wall coverings. The studs are exposed and flush with the panel on the back side, and covered by ½ inch of EPS on the outer side.

Consult local building codes for screw type, spacing, and wind loading while following stucco manufacturer’s specifications and referencing InSoFast testing noted below.

More information and links:

Guides, Brochures, and Comparisons:

| InSoFast Exterior Installation Guide | |

| Guideline for attaching exterior insulation with mechanical fasteners. | |

| Exterior Continuous Insulation with a Built-in Rainscreen | |

| Attaching James Hardie Products to InSoFast | |

| Exterior Retrofit Installation Guide | |

| Exterior Price Comparison | blog |

| ASTM D1761 Pullout and Lateral Load Testing | |

| Fasteners for Hardibacker fiber cement board, and metal lath stucco |