RMS InsoFast Basement Remodel

Compare the value of these different assemblies.

| Install Guide | Ordering Guide | Contact/Quote |

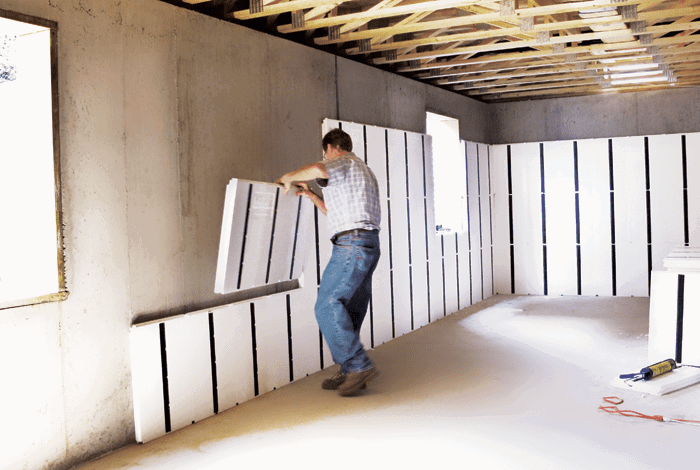

How does InSoFast measure up when it comes to value? We compare typical remodeling situations and draw a comparison between the “Lumber Stores,” materials purchases vs the InSoFast delivered method. The comparison should include factors like the cost, weight, and delivery of materials. We include the average number of parts and pieces you’ll have to deal with during your installation, an often over looked cost of material and handling. Finally consider the labor cost for installation. It will take at least week’s worth of labor to assemble and source lumber store materials. In-So-Fast is a one call and delivered system that you can install it in a week-end.

Our cost comparison does not include taxes, shipping or contractors associated with the traditional wood framing assemblies. InSoFast’s comparison INCLUDES the materials delivered curbside to your project including Do-It-Yourself simplicity.

Totals (including the InSoFast Panels) are based on material and pricing from Menards and Home Depot via Northeast regional zip codes (yes, prices and quality varies from region to region) as of 06/22/2022. We supply you with direct links so you can source local pricing… we do this because we know that we are a better and healthier choice.

The Answers

Small Project: 68 ft. × 7 ft. = 476 sq-ft. |

||

| Total Material Cost | Cost per Square Foot | |

| Traditional Wood Framing | $1,622.80 | $3.41 |

| InSoFast FP-2.0RW Panels | $1,534.80* | $3.15 |

| InSoFast FP-2.5RW Panels | $1,654.80* | $3.47 |

Large Project: 200 ft × 9 ft = 1,800 sq-ft. |

||

| Total Material Cost | Cost per Square Foot | |

| Traditional Wood Framing | $6,243.78 | $3.51 |

| InSoFast FP-2.0RW Panels | $5,503.80* | $3.04 |

| InSoFast FP-2.5RW Panels | $5,953.80* | $3.29 |

* We include curbside delivery

The Small Project Breakdown: 68 ft. × 7 ft. = 476 sq-ft.

Wood Framing

|

||||

| 2x4x8′ #2 Prime Treated bottom plate | 9 | @ | $5.48 | $49.22 |

| 2x4x8′ Studs – 16″O.C. framing | 56 | @ | $4.87 | $272.72 |

| 2x4x8′ Top plate | 17 | @ | $4.87 | $82.79 |

| 1″ Rigid foam insulation board (4’x8′) 2 layers | 30 | @ | $32.00 | $960.00 |

| Insulation board adhesive | 14 | @ | $10.68 | $149.52 |

| Tapcon 3/16 in. x 3-1/4 in. Concrete Anchors | 1 | @ | $27.98 | $27.68 |

| SS 16d framing nails for studs to bottom plate | 3 | @ | $9.19 | $27.57 |

| Nails – 16d framing nails | 1 | @ | $23.96 | $23.96 |

| Nails – 8d framing nails to toe nailing studs | 1 | @ | $23.96 | $23.96 |

| Shims | 3 | @ | $1.78 | $5.34 |

| Material cuts estimated: |

125 | |||

| Total Parts: | 466 |

|||

| Total Weight: | 1262 lbs. | |||

| Total Price: | $1,622.86 | |||

| Cost Per Square Foot | $3.41 | |||

InSoFast FP-2.0RW Panels

|

||||

| 4′ × 2′ × 2″ FP-2.0RW Panels as boxes of 40ft² | 12 | @ | $120.32 | $1,443.84 |

| PL Premium adhesive *sold by others | 10 | @ | $12.00 | $120.00 |

| Material cuts: | 9 | |||

| Total Parts: | 70 | |||

| Total Weight: | 187 lbs. | |||

| Total Price: | $1,563.84* | |||

| Cost Per Square Foot |

$3.28 | |||

* We include curbside delivery

InSoFast FP-2.5RW Panels

|

||||

| 4′ × 2′ × 2 1/2″ FP-2.5RW Panels as boxes of 40ft² | 12 | @ | $129.72 | $1,556.64 |

| PL Premium adhesive *sold by others | 10 | @ | $12.00 | $120.00 |

| Material cuts: | 9 | |||

| Total Parts: | 70 | |||

| Total Weight: | 199 lbs. | |||

| Total Price: | $1,676.64* | |||

| Cost Per Square Foot |

$3.52 | |||

* We include curbside delivery

The Large Project Breakdown: 200 ft × 9 ft = 1,800 sq-ft.

In this example, we are insulating all four walls. The floor-to-ceiling height is 8 ft. and the total length of the walls to be covered is 200 ft. (60 + 40 + 60 + 40). Multiplying the total length by the total height (200 × 9), this project requires material that will cover 1,800 sq-ft.

Wood Framing

|

||||

| 2x4x8′ #2 Prime Treated bottom plate | 25 | @ | $5.48 | $137.00 |

| 2x4x10′ Studs – 16″O.C. framing | 155* | @ | $10.24 | $1,587.20 |

| 2x4x8′ Top plate | 52 | @ | $5.48, | $253.24 |

| 1″ Rigid foam insulation board (4’x8′) 2 layers | 113 | @ | $24.97 | $3,616.00 |

| Insulation board adhesive | 46 | @ | $9.61 | $442.06 |

| Tapcon 3/16 in. x 3-1/4 in. Concrete Anchors | 2 | @ | $27.68 | $55.36 |

| 16-Penny Hot-Galvanized Nails for bottom plate | 10 | @ | $9.19 | $91.90 |

| Nails – 16d framing nails | 3 | @ | $23.96 | $46.44 |

| Nails – 8d framing nails to toe nailing studs | 2 | @ | $23.96 | $47.92 |

| Shims | 6 | @ | $1.78 | $10.68 |

| Material cuts estimated: |

201 | |||

| Total Parts: | 1466 | |||

| Total Weight: | 3783 lbs | |||

| Total Price: | $6,313.24 | |||

| Cost Per Square Foot |

$3.51 |

|||

*155 stud scraps 16 1/2″ long

InSoFast FP-2.0RW Panels

|

||||

| 4′ × 2′ × 2″ FP-2.0RW Panels as boxes of 40ft² | 45 | @ | $120.32 | $5,414.40 |

| PL Premium adhesive *sold by others | 35 | @ | $12.00 | $420.00 |

| Material cuts: | 25 | |||

| Total Parts: | 240 | |||

| Total Weight: | 767 lbs. | |||

| Total Price: | $5,834.40* | |||

| Cost Per Square Foot |

$3.24 | |||

* We include curbside delivery

InSoFast FP-2.5RW Panels

|

||||

| 4′ × 2′ × 2 1/2″ FP-2.5RW Panels as boxes of 40ft² | 45 | @ | $129.72 | $5,837.40 |

| PL Premium adhesive *sold by others | 35 | @ | $12.00 | $420.00 |

| Total Parts: | 240 | |||

| Total Weight: | 890 lbs. | |||

| Total Price: | $6,257.40* | |||

| Cost Per Square Foot | $3.48 | |||

* We include curbside delivery

Why work so hard? We’ve been asking that since day one and everything we do and make starts there. Crafting simplicity while maintaining a feature-rich product is far from simple and there’s a wide history of complex building techniques that can attest to it. Today, simplicity is a hot trend and possibly one in danger of becoming sales jargon. So, with the threat of buzz words ever-looming in dark corners, we feel it’s important to throw a spotlight on everyone – even us! Here’s a list of manufacturers of basement finishing products who claim the “why work so hard” ethic. Go check ’em out because the right decision is your decision.

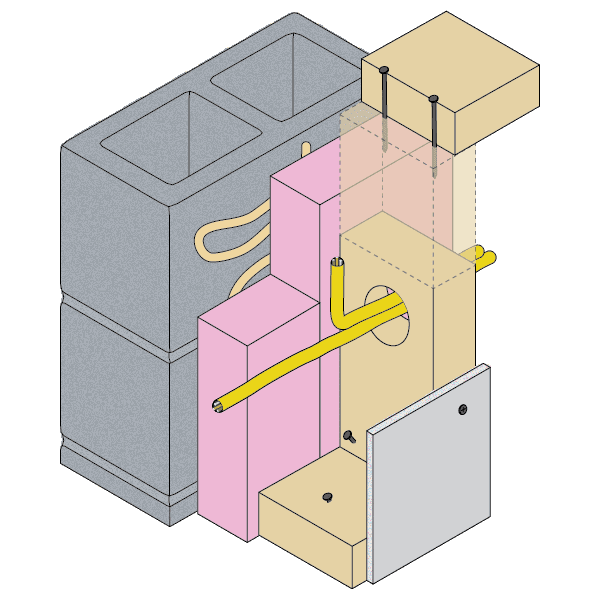

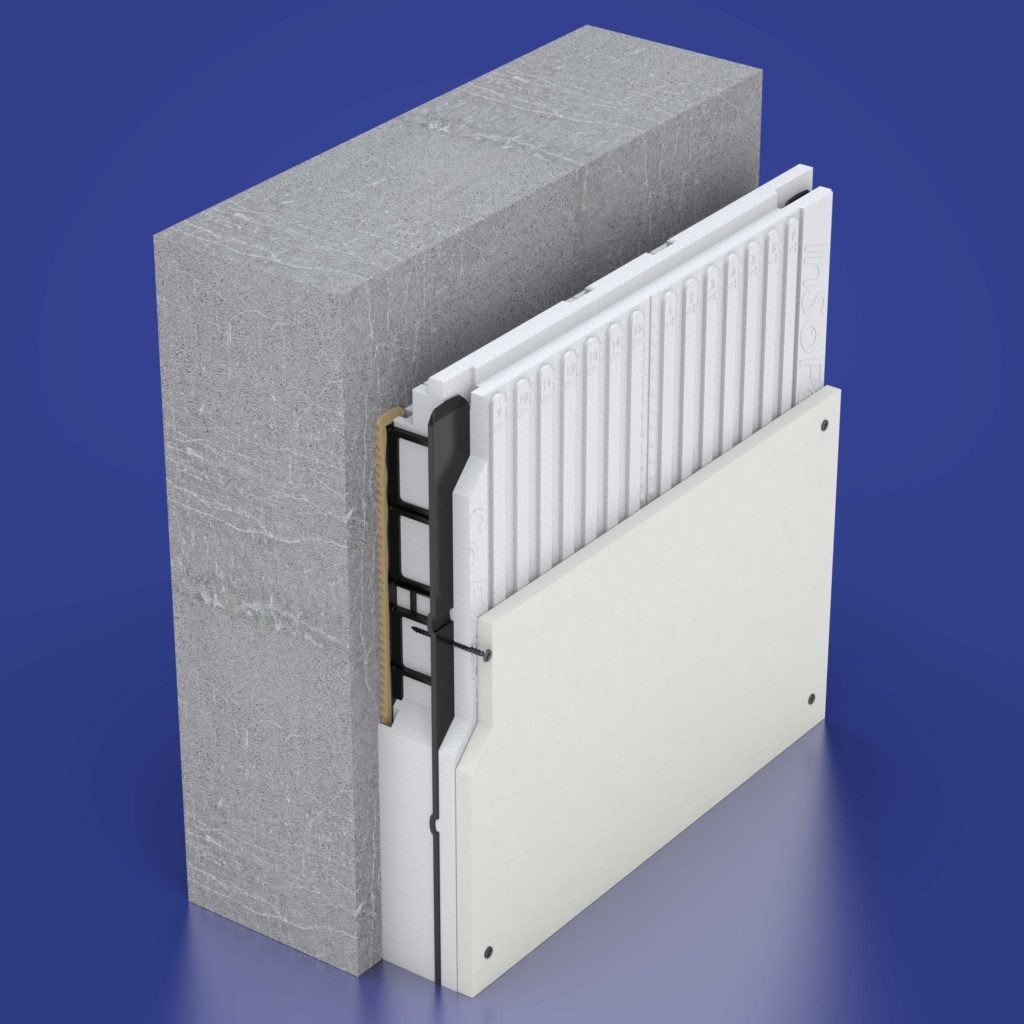

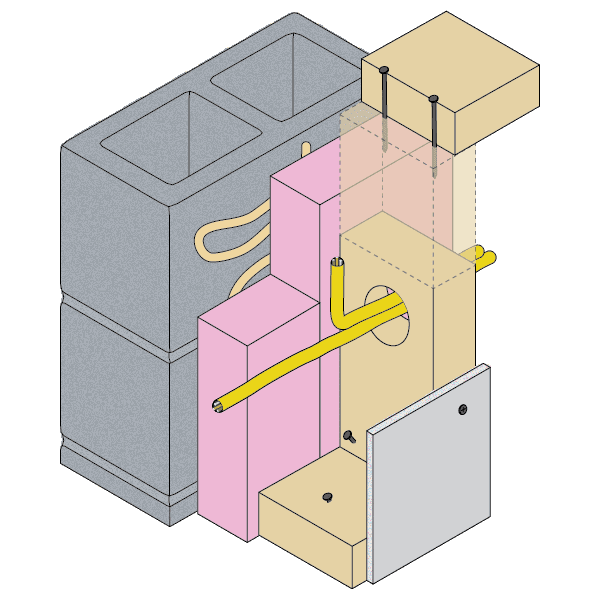

Electrical Labor savings using the panels

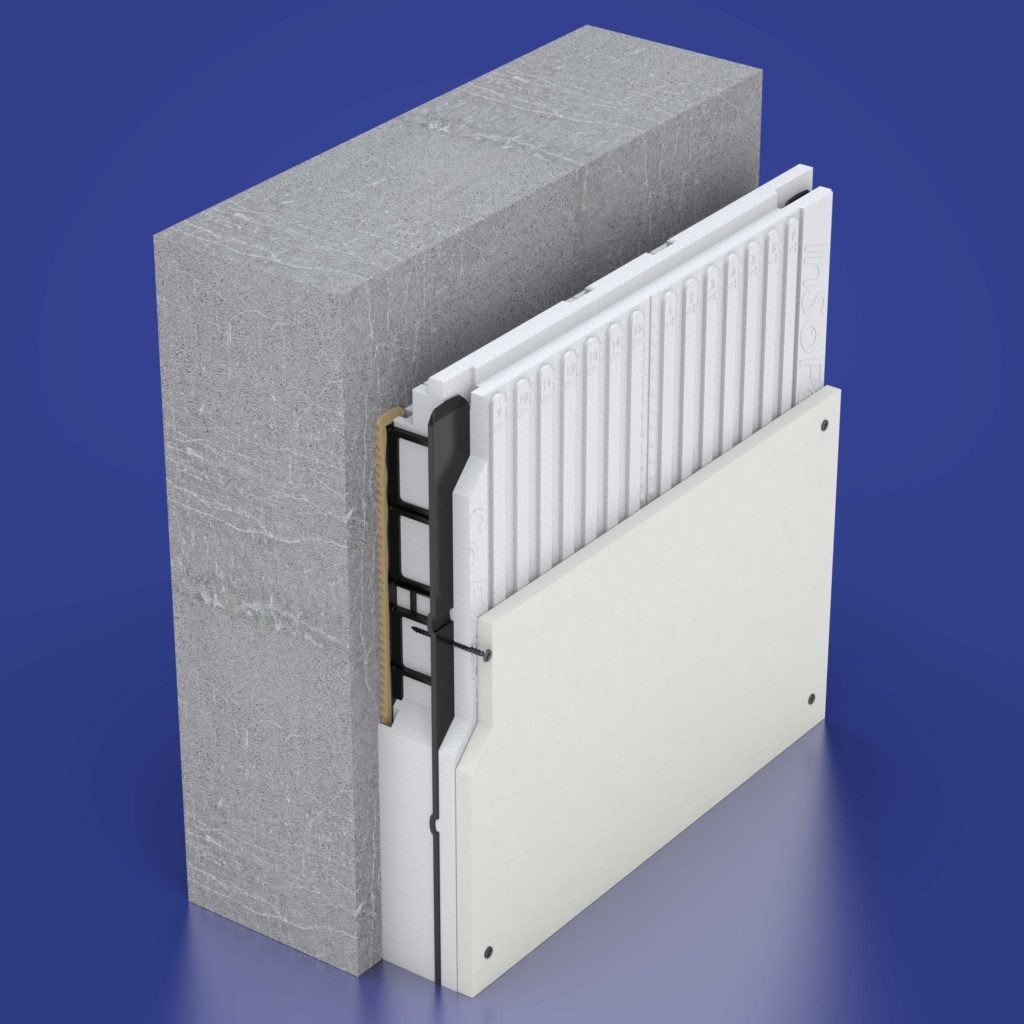

The diagram for InSoFast assembly demonstrate how electric can be integrated but this is not included in the material price or labor calculations. InSoFast panels include built-in chases running both vertically and horizontally across each panel and boxes can be installed anywhere necessary. The traditional method generally requires drilling a space through each stud and threading the wires through before the insulation (fiberglass) and drywall can be installed. Electrical boxes must be held in place against the available wood studs.

One more important thing: Even as competitors, we all agree that fiberglass or rockwool insulation with a plastic vapor barrier is a terrible way to remodel a basement. It is a recipe for mold, rot and poor indoor air quality that can create potentially unhealthy conditions.

SEE: What to Know About Basement Insulation

For more information go to: University of Minnesota and Oak Ridge National Laboratory Web Page

For more information https://www.builderscalculator.com/framing-calculator/