Does Energy Savings Makes ‘Cents’ for you?

Adding insulation to your basement is one of the most effective investments you can make for your home. The payback can begin in only 4.4 years! But in order to make the renovation worthwhile, there are a few factors to consider before you start insulating. The importance of addressing mold and moisture problems among other tricky conditions is crucial in avoiding costly mistakes. We’ve gathered a few answers to some commonly asked questions that will hopefully help you make the right decisions during the insulation process. Also from this page there will be a number of links to articles that will help you decide if investing into remodeling your basement is worth it to you. (Energy-Savings-Makes-Cents)

The above video is an in-depth look at the science behind foundation insulation effectiveness. Narrated by Pat Huelman, the Cold Climate Housing Coordinator for the University of Minnesota, it’s a highly recommended half-hour if you’re serious about getting the most from your basement insulation project. Feel free to keep reading though, it’ll be here when you return.

Is insulating your basement a worthwhile investment?

The US Department of Energy funded a study with the Building Science Consortium which found that, “Heat loss from an uninsulated basement can account for up to one third of the heating cost in the average home. Which is pretty obvious since a basement is 1/3 of your average home. Think of your basement like standing outside during a snowstorm with a hat, coat, scarf, a puffy down coat, in a pair of shorts.

Insulating the upper half of the basement wall with R-5 insulation reduces the heat loss from the basement by approximately 50%. Full height insulation (R-5) in the same area reduces heat loss from the basement by approximately 70%”. That’s a pretty drastic reduction in heat loss! What starts as a simple weekend installing InSoFast panels in your basement, will lead to a lifetime of drastic savings on your energy bill.

Will doubling the insulation double my savings?

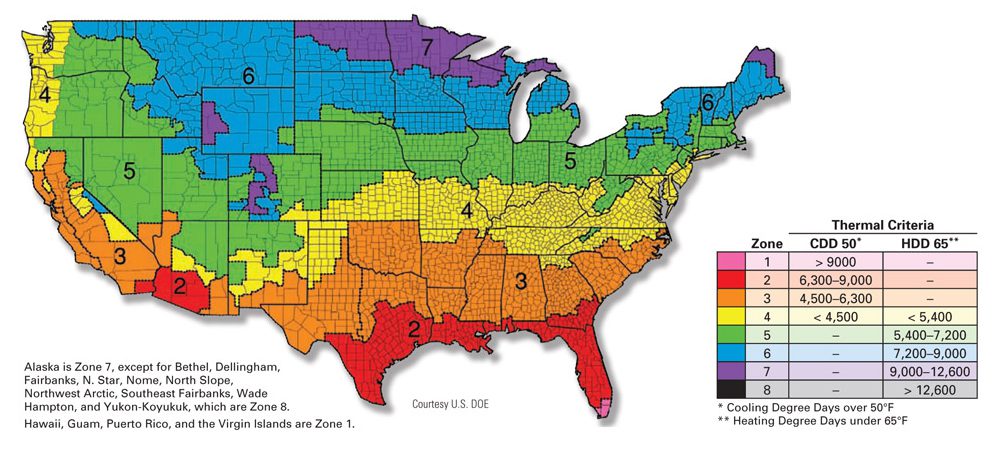

Nope! Like all things there is a law of diminishing return that kicks into gear. A study from the US Department of Energy found that over-insulating your basement can be more costly with little to zero payback. Adding an additional R-10 of insulation to basement walls may take over 35 years to payback the initial investment. Building codes do offer guidance on what the right R-Value is for your climate zone.

Find your local State R-Value Code Requirements

Over-insulation can also lead to mold problems. Since insulation decreases the flow of energy, it decreases the energy needed for moisture to evaporate. Hidden Moisture build up behind your finished wall could become problematic if you use the wrong materials. The more insulation you add to a basement wall system, the more critical it is to pick materials that won’t rust, rot, or decay.

What kind of conditions lead to mold growth?

How to prevent mold growth in a basement.

Basements are often dark, moist, spider ridden dungeons- the perfect place for scary story telling. They are also notorious for problems with water intrusion, cold temperatures, humidity and mold. Since mold needs water, food, oxygen, and an environment between 40-100 degrees F to thrive, basements provide the perfect home for mold.

It may seem bizarre that mold thrives on basement walls, since fungus cannot grow on inorganic surfaces like concrete and metal. But since these surfaces usually contain the presence of dirt and dust, the fuzzy stuff is able to thrive on concrete when moisture is present. Mold also decomposes dead organic material, meaning it grows very easily on wood and drywall. The spores start growing only 24-48 hours after a water leak, so it’s important to act fast when dealing with water in your basement.

Why does the lack of insulation on basement walls lead to mold and mildew problems?

When you pull an ice-cold drink out of a foam cooler on a humid summer day, you will almost immediately notice condensation forming on the sides of the can. This is exactly what happens to the cold walls of a basement. As the walls become damp, dust attaches to the walls and mold begins to grow. If you put the same insulation from the foam cooler on the basement wall, the condensation is stopped. The moisture control channels engineered into the InSoFast panel prevent water from collecting at the surface by redirecting the flow of moisture.

How do I remove mold and avoid future problems before I finish my basement?

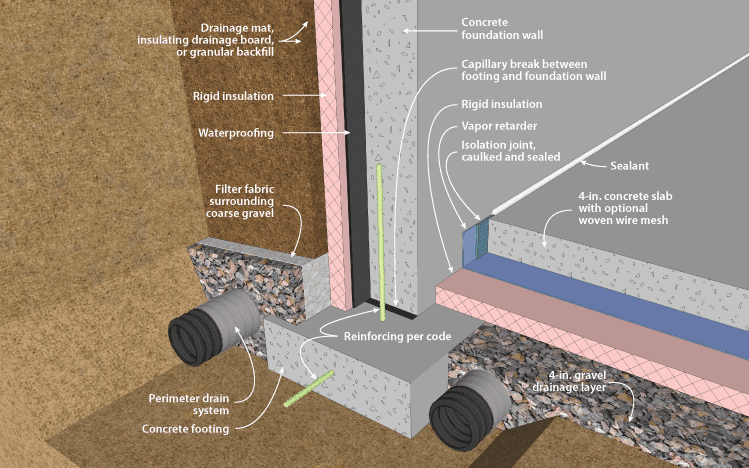

The first step in tackling your basement renovation project involves simple ingredients-Mold Stain and Mildew Stain Remover and elbow grease! Start by using a bucket of remover and water thoroughly scrub mold, dirt and debris off the walls. Make sure you rinse and let the walls dry completely. Before blocking the walls with insulation you also need to correct any water intrusion problems that already exist. There are a variety of different concrete sealers perfect for correcting minor leaks within walls. There are penetrating sealers that soaks into the concrete and reacts with the lime to form a crystalline glass-like water proofing. This product can only be used on unpainted concrete surfaces. The second type of concrete sealer comes in the form of paint. The two methods can be combined together to achieve an even higher level of protection. However the best defense is still good design keeping the water away from the house.4.a

Sources:

1. Understanding Basement Insulation

2.What You Need to Know About Mold, Research Report – 0208

Why does the lack of insulation on walls lead to mold and mildew problems?

When you pull an ice-cold drink out of a foam cooler on a humid summer day, you will almost immediately notice condensation forming on the sides of the can. This is exactly what happens to the cold walls of a basement. As the walls become damp, dust attaches to the walls and mold begins to grow. If you put the same insulation from the foam cooler on the basement wall, the condensation is reduced to near zero. The moisture control channels engineered into the InSoFast panel prevent water from collecting at the surface by redirecting the flow of moisture.

Should there be a vapor barrier if my walls are waterproofed?

Imagine that a basement is a hull of a ship floating on a sea of wet mud. 100% humidity 100% of the time, soil/mud’s moisture can wick through by (capillary action), a solid material like concrete and into your basements. Basement walls are essentially heavy wet sponges. The best practice walls should have been damp-proofed or better yet waterproofed on the exterior and a drainage plane/capillary break installed.

If you have an older home…I would not count on proper details. In the past, older homes did not need to follow what is now proper detailing measures. Basement were uninsulated and unfinished, often called root cellars, so not being damp-proofed allowed for inward drying and a pretty stable (environment) always damp. Finishing a basements changes those conditions, always damp is not a good option. Moisture will constantly migrate through the foundation, (wet seeks dry). An interior insulation barrier like fiberglass just slows down this moisture movement towards the drywall (like a screen door slows down the rain moisture can’t dry fast enough and that will lead to mold and mildew. The wrong insulation and (organic) framing used upstairs method will be a disaster. That is why InSoFast panels have no food value and are considered a 2″ or 2 1/2″ thick insulated vapor barrier that will not to support mold growth.

Do I need a vapor barrier to prevent mold?

Not if you use InSoFast! It’s no longer considered good building practice to use a plastic sheet vapor barriers with wood framing below grade, since moisture problems are inevitable. If the wall happens to get wet for any reason, the vapor barrier prevents it from drying. InSoFast is a Class III vapor barrier that allows drying to the inside and is not affected by moisture. With that said we still want you to air seal the InsoFast panel at all penetrations like electrical boxes and at the floor and top of the wall. We want to limit dust filled moisture ladened air from coming into contact with the cool concrete. The channels on the back of our panels are gravity drains and NOT air channels.

How do I guard against moisture and radon problems to in a basement?

|  |  |

Not a simple answer. Remember that a basement is like the hull of a boat floating on a sea of wet mud, leaving a hole in the bottom of a boat can be problematic. Just applying a penetrating radon sealer on bare concrete walls and floors may not be enough. Sealing any cracks in the concrete and around any penetrations will help avoid future radon problems but not necessarily solve the issue. Open interior french drains can lead to big problem.

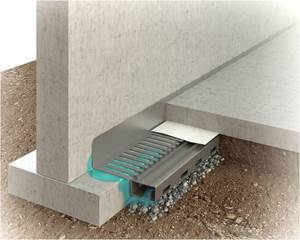

See our webpage about: Perimeter Drainage Systems for Basements

InSoFast panel interfacing with an interior french drain system.

Radon enters the home through the following areas:

- Crawlspaces

- Cracks in the foundation & walls

- Floor drains

- Pipes

- Sump pumps

Radon gas can enter both old and new homes, regardless if there are visible cracks or not. At InSoFast we are trying to build better, healthier, safer, insulated basements if you are going to spend the money to redo your basement do it right, get it tested for radon.

This particular detail was developed by one of our partners to address another leak.. Soil gas See: 90960 InSoFast Active Radon or Moisture Control System.