| Install Guide | Ordering Guide | Contact/Quote |

Locks Tight

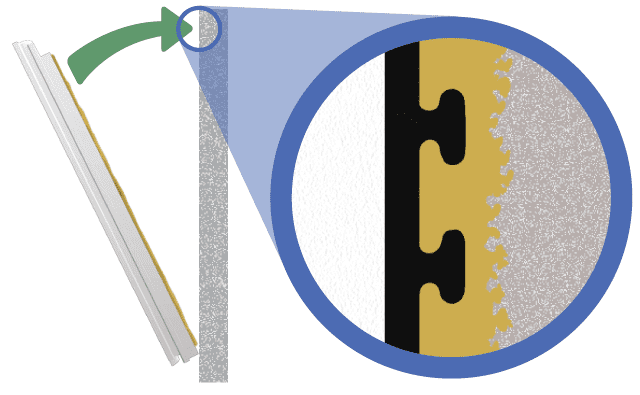

Like the name of the adhesive manufacturer, Loctite, our engineered patented stud is designed to form a tightly locked bond. When a bead of adhesive is run along the stud’s ribbing it forms hundreds of solid interlocking dovetails, a design renowned for high tensile strength. Adhesive also bypasses the structural stress associated with drilling holes in a wall.

GreenGuard Certified Adhesive:

One of the many reasons we recommend Loctite PL Premium is it has the GREENGUARD Certification. It is important to us that you use an adhesive that has low chemical emissions, improving the quality of the air in which the products are used.

Apply adhesive to the ribbed stud surface on the InSoFast panel/insulated stud. Press the bonding surfaces firmly together. The panels/studs may be re-positioned within 20 minutes after applying the adhesive. If bonding two non-porous surfaces (such as InSoFast panel/studs, to metal or fiberglass), add water in the form of a very light or atomized spray from a plant mister bottle to the adhesive extruded on the stud, this accelerates the adhesive set time. When adding moisture re-positioning time is reduced. If needed use mechanical support for 24 hours while the adhesive cures. When bonding InSoFast panels/studs, avoid cure and surface temperatures above 90°F (32°C).

Loctite PL Premium 3X or LePage PL Premium

Overview / Technical Data

InSoFast panels were designed with simplicity in mind and we would argue that gluing them is not only the easiest method of installation but often the most effective. Third-party testing has shown the adhesive bond strength of our studs to have 108psi of holding power. This means each adhered panel is capable of holding over 5,000lbs!

Testing was conducted using Loctite PL Premium’s 3X Stronger Construction Adhesive, (in Canada it is marketed under the LePage PL Premium brand,) on clean concrete surfaces. It is the only adhesive we have tested. Other formulas and brands may not work as expected.

Important Notice: Container Surface Temperature Applications

When bonding EPS and XPS foam insulation, use above 40°F (4°C) and avoid cure and surface temperatures above 90°F (32°C). Surfaces must be clean, dry and free of frost, grease, dust and other contaminants. Pre-fit all materials and protect finished surfaces. If using cartridge format, cut nozzle at a 45° angle to desired bead size and puncture inner seal. Be very careful not to allow Loctite® PL® Premium to cure on a finished surface.

Cold Weather Tips:

Interior Installation

Heating the interior of the container will not be sufficient for the adhesive to cure because the insulation panels will not allow heat to transfer to the container surface. It is recommended to either move the container to a heated area or tent and heat the exterior until the adhesive has cured.

Exterior Installation

The interior of the container can be heated until the adhesive has cured. See Cold Weather web page.

Interior and Exterior Installation

Install the exterior panels first while heating the interior. Allow adhesive to cure before installing interior insulation.

General Safety

Even though the adhesive is odorless, it is important to note its strength and abilities. Always wear disposable gloves and never allow PL Premium to cure on a finished surface.

Application Process

-

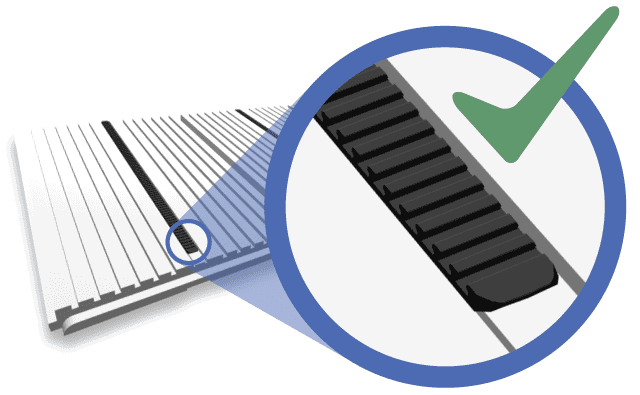

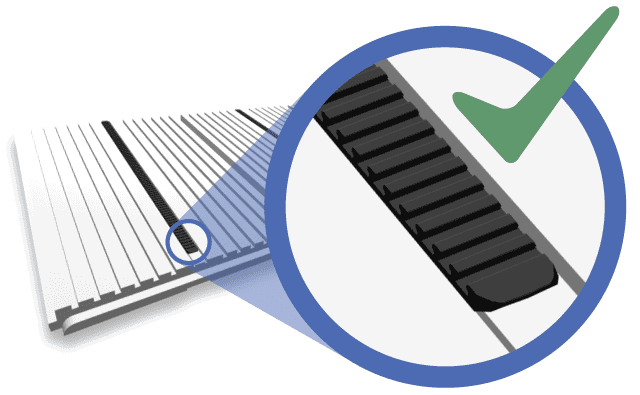

1. Find the Ribs

Make sure you are gluing the ribbed side of the studs. The front side is smooth and will not form a strong mechanical bond with the adhesive. Quick Tip: You can speed up your installation by pre-stacking the panels with rib-side facing up, ready for adhesive.

Make sure you are gluing the ribbed side of the studs. The front side is smooth and will not form a strong mechanical bond with the adhesive. Quick Tip: You can speed up your installation by pre-stacking the panels with rib-side facing up, ready for adhesive.-

2. Apply Adhesive

Run a ⅜-in bead of adhesive along all 3 studs. If you are placing the panel on the edge of a wall or in a corner, run a bead directly on the foam at that edge (see: dashed line). This will ensure a solid-backed attachment. Again, it is only necessary at corners and anywhere you cut a panel to fit around openings.

Run a ⅜-in bead of adhesive along all 3 studs. If you are placing the panel on the edge of a wall or in a corner, run a bead directly on the foam at that edge (see: dashed line). This will ensure a solid-backed attachment. Again, it is only necessary at corners and anywhere you cut a panel to fit around openings.-

3. Press in Place

Check that your panel is tongue-side up, with the rib-side facing the wall and that any interlocking edges meet. Press firmly against your wall. Don’t be alarmed if it feels a little spongy at first. PL Premium takes about 20 minutes to set and 24 hours to cure. It can form a “liquid shim” spanning gaps of up to ⅜-in and effectively tighten up small irregularities in a wall’s surface. On walls that are subject to peeling or flaking paint, it is important to supplement the installation of InSoFast panels with mechanical fasteners such as Tapcon® screws or Perma‐Grip nails. See: Installation > Screws and Fasteners

Check that your panel is tongue-side up, with the rib-side facing the wall and that any interlocking edges meet. Press firmly against your wall. Don’t be alarmed if it feels a little spongy at first. PL Premium takes about 20 minutes to set and 24 hours to cure. It can form a “liquid shim” spanning gaps of up to ⅜-in and effectively tighten up small irregularities in a wall’s surface. On walls that are subject to peeling or flaking paint, it is important to supplement the installation of InSoFast panels with mechanical fasteners such as Tapcon® screws or Perma‐Grip nails. See: Installation > Screws and Fasteners

Estimating Adhesive Quantity

Estimating adhesive has variables beyond our control, the condition of the wall, and how accurate the tradesmen is with a glue gun? The adhesive manufacturer’s technical sheet states, “A 3/8” (9.5 mm) bead extrudes approximately 38 ft. (12 m).“

In a perfect world. When PL Premium 3x adhesive is applied a ⅜” bead on the backside of the stud’s ribbed surfaces roughly equates to 7 InSoFast panels or 56 square feet of adhered wall. (adhesive coverage will vary)

The adhesive follows the “Goldilocks Rule,” too much, too little, and just right. Doing just right you can expect that 1 large 28-fl oz tube will cover 21 of our studs (3 studs per panel for 7 panels).

Other considerations additional adhesive should be included for securing the panels at openings like windows, doors and corners.

1 large 28-fl oz / 828 mL tube = 21 (22″ studs) or 7 panels for 56 Square feet of glued InSoFast wall surface.

- We recommend that you estimate approximately 10% waste or

- 1 tubes of the adhesive = 50 Square feet of wall.

To verify that enough adhesive is used, press the panel into place. Pull the panel back and check to see if the adhesive has spread out beyond the full width of the stud. It is normal for the panel to “float out” from the side of the wall when it is accommodating irregularities the adhesive will bridge gaps up to 3/8″. Additional adhesive may be necessary in some areas.

|

POLYURETHANE CONSTRUCTION ADHESIVE Rough estimate for 28 ounce tubes of adhesive required |

||

| Square Feet |

InSoFast 2.0 or 2.5 Boxes |

LOCTITE® PL PREMIUM® |

| 800′ | 20 | 16 |

| 1200′ | 30 | 24 |

| 2000′ | 50 | 40 |

| 3600′ | 90 | 72 |

Adhesive Testing

If you are unsure about the conditions of your walls, we recommend performing an adhesive test. Find a scrap 2×4 measuring at least 6 inches long and run a 3/8-inch bead of adhesive along it. Press the “test block” against the wall with one end resting on the floor to keep it from sliding down. Support it in place if necessary. You’ll need to wait 24-48 hours for the adhesive to cure, but keep in mind that PL Premium takes 14 days to reach it’s full strength.

When the curing time has passed you are ready to test the strength of the bond. Try to pry the test board off the wall. If you can manage to pull it off with your hands, you will need to mechanically fasten the panels to the wall.

See: Installation > Screws and Fasteners

When you begin your InSoFast installation, check to make sure you are using the right amount of glue. Pull back a freshly adhered panel and check for adhesive transfer to the wall. You should see about 1/2-inch wide adhesive transfer to the wall.

Do not install screws or mechanical fasteners until the adhesive has completely cured. (usually about 24hrs)

Safe and Reliable

In many cases, construction adhesives are actually a more reliable method of attachment. In particular, Loctite’s 3X Stronger formula is designed to cure 3 times stronger than average solvent-based varieties. A single bead can outperform concrete screws spaced 6 inches apart.

PL Premium is not a solvent-based adhesive. It is compatible with all types of foam and it’s completely odor-free. Additionally, it does not shrink as it cures. This property allows it to act as a predictable “liquid shim” which can span and fill gaps of up to ⅜-in.

Cast in Place-Not Glued

The glue does not stick to our polypropylene stud?

If you read the adhesives manufacturer’s application information it states that the glue will not stick to polypropylene, our stud is made from polypropylene. The glue bonds to steel, wood, concrete and many other materials at many 100’s of pounds of pull-off.

The design of the dovetail glue strip accounts for this non stickiness. The polyurethane adhesive expands around dovetailed “T” strip stud and as it cures it will (harden) cast-in-place the InSoFast stud. This cast-in-place function is one of our most important patent claims.

The glue is not sticking!

Yes it is! Trust the glue. Often that the viscosity (stickiness) of the glue will vary

Simple

It’s easy! PL Premium remains re-position-able for up to 20 minutes without disrupting its bond strength. In 24 hours, your project is ready for drywall.

We designed InSoFast Panels with you in mind and PL Premium 3X Stronger was part of our decision process. We want your InSoFast project to be as simple as possible to install, so that you can quickly experience the benefits of an insulated home and/or office.

| Install Guide | Ordering Guide | Contact/Quote |