Corners, Intersecting Walls, and Cabinets, attached to InSoFast Panels

How to handle Inside and Outside Corners

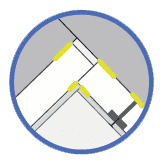

| Inside Corners Corners that form an inside angle |

Outside Corners Corners that protrude into a room |

|

|

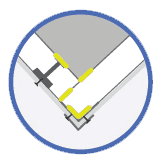

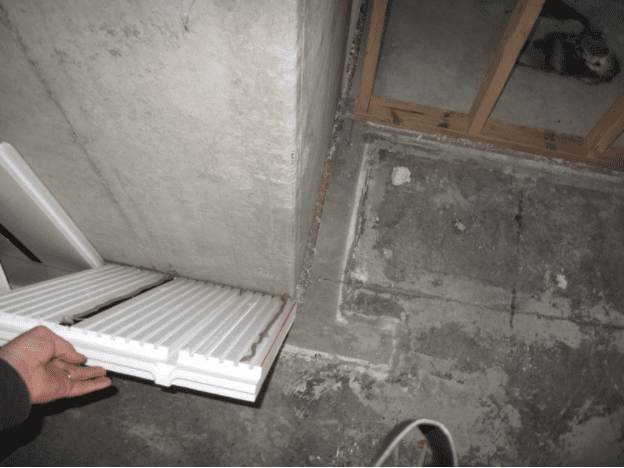

These outside corners need a metal corner bead attached to them. If necessary, mark and cut the first panel flush with the corner. You will use the cut off piece to wrap around the other side of the corner.

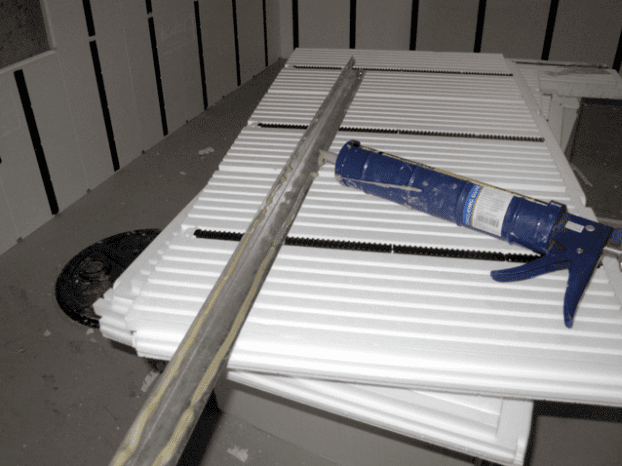

Install the first panel flush with the corner edge of the concrete wall making sure to place a solid-backing bead of adhesive near the edge of the cut. On the cut-off piece or second panel run two beads of adhesive. The first bead, running approximately 1″ from the edge, will bond the foam of the InSoFast panels together at the corner. The second bead, running approximately 3″ from the edge of the panel, will bond the foam of the InSoFast panel to the concrete.

|

|

- Place beads of adhesive on the backside of the sheet metal utility corner angle. Utility corner angles are available at drywall supply yards.

- Press into place on corner. Hold in place with duct tape if necessary.

- Hang drywall using all-purpose drywall screws.

Install all of the InSoFast panels around the perimeter walls before building interior partition walls to maintain the continuous insulation barrier. Butt intersecting wall directly to the InSoFast panels. You can apply a bead of construction adhesive to the backside of the stud where it will come in contact with the InSoFast panels. Note that the frame wall is independent from the InSoFast panels the intersecting wall is fastened at the bottom plate and top plate.

Optionally, if you did not adhere the intersecting wall stud to the InSoFast panels, you can use a concrete screw to connect the stud through the InSoFast panel into the concrete.

Mounting heavy items, such as cabinets, shelving, or a mounting bracket to an InSoFast wall is easy. When installed over masonry heavy objects can be fastened anywhere on the wall by simply using the appropriate length masonry fastener like a Tapcon® anchor. Because the drywall is backed solid with the rigid foam of the InSoFast panel, there is no need to locate a “stud” when fastening through the foam directly into the concrete which serves as a continuous solid structural backing behind the entire wall.

Third party testing shows that the copolymer studs have a holding power for attachment equivalent to that of commercial grade steel studs (20ga) using all-purpose drywall screws.

Alternatively light gauge metal backing or strapping can be attached to the InSoFast stud to provide continuous attachment support.