Side Wall Inserts for Shipping Containers

| « How to » | « Order » | « Contact » |

Since releasing our Side Wall InSerts we’ve seen customers from all over the country use them to insulate their shipping containers.

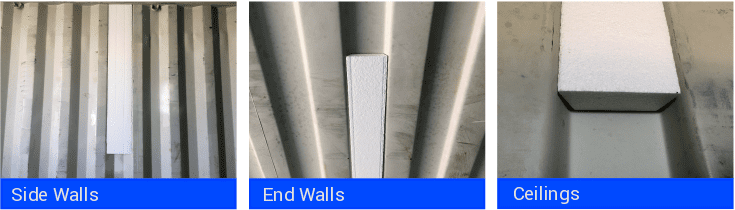

This month InSoFast introduces two new variations of our InSerts: InSoFast InSerts for End Walls and Ceiling applications. These new InSerts are custom designed to fit the varying depths of the container’s corrugated walls, making them simpler to install in the different zones of your container.

More importantly our InSerts address one of the biggest concerns in shipping container construction: is the container’s metal wall “sweating”?

A container home is like a submarine; it’s nearly an airtight living environment. This presents a unique challenge. Humidity gets trapped inside of the container which can lead to problematic condensation, aka: “Sweating Metal”. In this scenario proper ventilation and air conditioning is actually more important than the insulation.

When you pull an ice-cold drink out of a foam cooler on a humid summer day you will almost immediately notice condensation forming on the sides of the can. This is what happens to the cooler metal walls of shipping containers. Any insulation strategy will work to prevent condensation with the right size HVAC equipment, yet no insulation system will work without it.

Fibrous insulations like rockwool, cotton, and fiberglass can work but they are difficult to install correctly. If there are any breaches in the wall, warm moist air will migrate to the surface of the containers metal wall. This can lead to condensation, reduction of R-Value and mold growth.

Spray foam is another alternative but it presents other challenges and is tricky to install. When the spray foam is in place and the stud framework is built over top, there will be hidden air space behind the drywall finish. Moisture can then be trapped within the spray foam.

Our system addresses all of the problems above. The combination of InSoFast InSerts and InSoFast Panels fill up all of the hidden airspace behind the drywall with solid closed cell foam. It provides a skin tight framing and insulation to support your drywall finishes. We’ve engineered the InSerts to fill the varying corrugated negative spaces of shipping container walls. Our UX and EX panels can then be installed directly over the InSerts, leaving a smooth surface for installing drywall and other wall finishes.

To learn more about the installation process, refer to Ashley’s container project in Texas. She used our Side Wall InSerts along with InSoFast UX 2.0.

TIP- For those of you who are planning to buy the really dented and well used containers- a little bit of hammering or sanding to round out the edges may be needed to fit the InSerts bang them out.