Wood Jamb Method for Windows and Doors

Cut out any openings First

Cut out of any openings before installing the InSoFast panels or inserts. There are many methods for installing windows and doors. We will be showing one method for utilizing a wood jamb when a structural header is not required. Whatever method you choose to use, the jambs or framing for any openings should be done before the InSoFast panels are installed.

Quick Wood Jamb Method

On a 2×4, trace the corrugation and cut apart. This creates the interior and exterior part of the bottom and top jamb. The side jambs are created in a similar manner, cutting lengthwise with a circular saw set to the angle of the container to accommodate the corrugation.

- Use caulk and screws on each side to join the jambs together, sandwiching the container in between.

Put a generous bead of the Loctite PL Premium onto both halves of the wood buck. This will provide a tight air seal and bond.

Attach the exterior 1/2 of the wood buck through the pre-drilled holes in the container wall.

- The wood jamb should protrude inward 2″ so that it will be flush with the InSoFast panels.

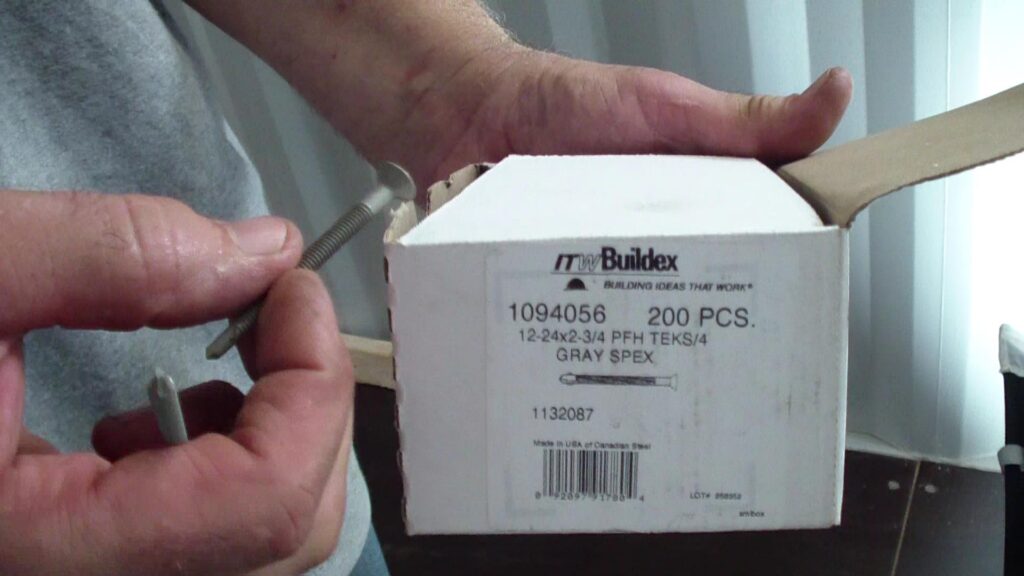

To fasten the interior half of the buck we used special fasteners for ITW with a drill bit and metal wings that over drill the wood then break-off to allow the screw to anchor itself to the steel container wall.

Manufacture’s Tech Sheet: TEK ITW buildex_Wood-to-Metal Fasteners.PDF

-

The interior 1/2 of the wood buck’s 2×6 holes were counter sunk.

The window bucks are complete and ready to finish. Next step is to insulate the interior walls with the CX44 panels.

Manufacture’s Tech Sheet: TEK ITW buildex_Wood-to-Metal Fasteners.PDF

- Flash, seal, and install the window per manufacturer’s instructions.

Installing InSoFast Panels around Windows/Doors

Sealing around Windows/Doors

| «How to» | «Order» | «Contact» |