Product Overview

The corrugated infill inserts for the ridges of shipping container’s ceilings. There are 56 Ceiling Inserts per box. The Ceiling Inserts are a part of a comprehensive approach of insulating a shipping container.

- I-CEI Ceiling Inserts – 4’ (56 pcs.) 224 Lineal Feet

- One box per 20′ Container Ceiling 160 sq-ft.

- (28) 8′ long insert

1 box contains 56 ceiling inserts for a 20' ceiling

-

Ceiling inserts fit the indented space in the container’s ceiling to reduce air spaces where condensation can occur. The inserts are a part of a comprehensive approach to insulate a shipping container’s ceiling. There are 56 Ceiling Inserts per box.

- Ceiling Inserts – 4’ (56/box) 160 s.f. coverage

-

UX 2.0 or EX 2.5 (5 panels/box) 40 s.f.

-

One 20 Container Ceiling would require 4 boxes of the UX 2.0 or EX 2.5 and 1 Box of ceiling insert

-

One 40 Container Ceiling would require 8 boxes of the UX 2.0 or EX 2.5 and 2 Box of ceiling insert

-

-

- Ceiling Inserts – 4’ (56/box) 160 s.f. coverage

Ceiling inserts fit the indented space in the container’s ceiling to reduce air spaces where condensation can occur. The inserts are a part of a comprehensive approach to insulate a shipping container. There are 56 Ceiling Inserts per box.

- Ceiling Inserts – 4’ (56/box) 160 sq-ft. coverage.

|

|

|

Ceiling InSerts One box of Ceiling Inserts covers 224 Lineal feet of indents. |

|

|

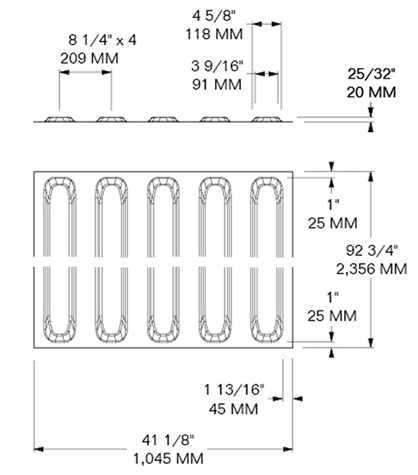

Dimensions |

48in x 4 5/8in x 13/16 in |

|

Coverage |

1.7 sq-ft |

|

R-Value ASTM C518 |

R-3.18 |

|

ASTM C578 Type II |

Closed-Cell, injection-molded EPS |

|

Canadian Standard CAN/ULC S701 Type 2 |

|

|

Foam Density |

1 lbs per cubic foot |

InSoFast engineered system of continuous insulation is perfectly suited for shipping container fabrication.

-

- Simple to install

- Why work so hard?

- Adaptable Attachment

- No Special Tools Needed

- Closed-cell high pressure fused EPS Insulation

- Continuous Insulation

- Engineered for Shipping Containers

- Lives up to its name: In So Fast

- Simple to install

Estimating and ordering is simple measure and add together how many 20′ long 8′ wide ceiling areas you need to infill with the inserts. Don’t overestimate, cut inserts can be re-used.

Inserts fill every indented void. One insert box will do a standard 20′ IEU container depending on your specific layout.

- 1 box (ins-ceil-56 = 56 pcs.) = (28) 8′ long inserts

POLYURETHANE CONSTRUCTION ADHESIVE

|

|

Green Guard Certified Adhesive:

In Canada the Glue is LePage PL Premium

Estimating Adhesive Quantity

Estimating the amount of adhesive YOU will use has variables beyond our control like condition of your walls and how accurate are you with a glue gun? The example below is for one side wall of a 20′ standard height shipping container you will need approximately 3 tubes of the adhesive. That is in a perfect world. PL Premium 3x adhesive is applied in a ⅜” bead on the backside of the studs onto the ribbed surfaces. We realize that a 3/8″ bead of glue is very subjective. It is important that there is enough adhesive to squish the dovetails on the back side of the stud when pressed to the container wall. Adhesive follows the “Goldie Locks rule, too much, too little, and just right To verify that enough adhesive is used, press the panel into place. Pull the panel back and check to see if the adhesive has spread out beyond the full width of the stud. It is normal for the panel to “float out” from the side of the container when it is accommodating irregularities in the container walls. Additional adhesive may be necessary in some areas. If you are doing it just right you can expect that 1 large 28-fl oz tube will cover 18 of our 24″ long studs or enough glue at a 3/8″ bead to cover 36 foot long bead of glue.

Additionally you will have to estimate for glue around openings like windows and doors.

1 large 28-fl oz. / 828 mL tube = 18 (24″ studs or inserts)

- CX-LP 46 (46 studs) = 46

- 46 ÷ 18 = 2 1/2 tubes of the adhesive

- I-SWI (30) = 1 tube of the adhesive

|

POLYURETHANE CONSTRUCTION ADHESIVE Rough estimate for 28 ounce tubes of adhesive required |

|||||||

| Container | Side Wall | End Wall | Ceiling | Total Walls & Ceiling | Floors | Swing Doors | Total Estimate |

| 20′- Standard | 3 | 2 1/2 | 6 1/2 | 13 | 1 1/2 | 3 | 18 |

| 20′- High Cube | 3 | 2 1/2 | 6 1/2 | 14 | 1 1/2 | 3 | 19 |

| 40′- Standard | 6 | 2 1/2 | 13 | 28 | 3 | 3 | 34 |

| 40′- High Cube | 6 | 2 1/2 | 13 | 29 | 3 | 3 | 34 |

Important Notice: Container Surface Temperature Applications

When bonding EPS and XPS foam insulation, use above 40°F (4°C) and avoid cure and surface temperatures above 90°F (32°C). Surfaces must be clean, dry and free of frost, grease, dust and other contaminants. Pre-fit all materials and protect finished surfaces. If using cartridge format, cut nozzle at a 45° angle to desired bead size and puncture inner seal. Be very careful not to allow Loctite® PL® Premium to cure on a finished surface.

Please read all the current Shipping, Purchasing & Returns *

| Product Code |

Number of Parts |

Per Box Dimension |

Cubic Feet Per Box |

Weight Per Box |

||

|

Length |

Width |

Height |

||||

|

CCEIL |

56 pcs. = 224 lnft |

12 1/2″ |

12 1/2″ |

49″ |

4.43 |

8 Lbs |