Product Overview

The EXi 2.5 is our most versatile interior/exterior grade panel it is optimized for masonry or framed construction it combines all the best features of continuous insulation that is ready for finishing.

Contains:

- SKU: FP-2.5 (5 panels 40 sq-ft.)

SKU: FP-2.5 = 1 box contains a total of 5 EXi 2.5 Panels covering 40 sq.ft.

R-10 Continuous Insulation

At 2½-in thickness, the EX 2.5’s closed-cell, injection-molded EPS foam body achieves R-10 insulation.

EPS is a non-toxic, inert insulation that maintains its R-value throughout the life of your building. Because it does not absorb moisture like open-cell types of bead board, it is rated highly for below-grade applications like basements. The EPS body has a fire-retardant material and serves as a Class III vapor barrier.

Strong Mold-Resistant Studs

Each panel is co-molded with three high-strength polypropylene studs that align every 16-in O.C. The anterior surfaces are fully embedded by a ½-in of insulation while the posterior surfaces feature ribbed dovetails for adhesive applications against interior concrete, stone, metal or brick walls.

They provide a straight surface that can support drywall attachment and exterior finishes as well as adornments like cabinets and TVs. They are not prone to moisture damage, and do not conduct heat along a wall system.

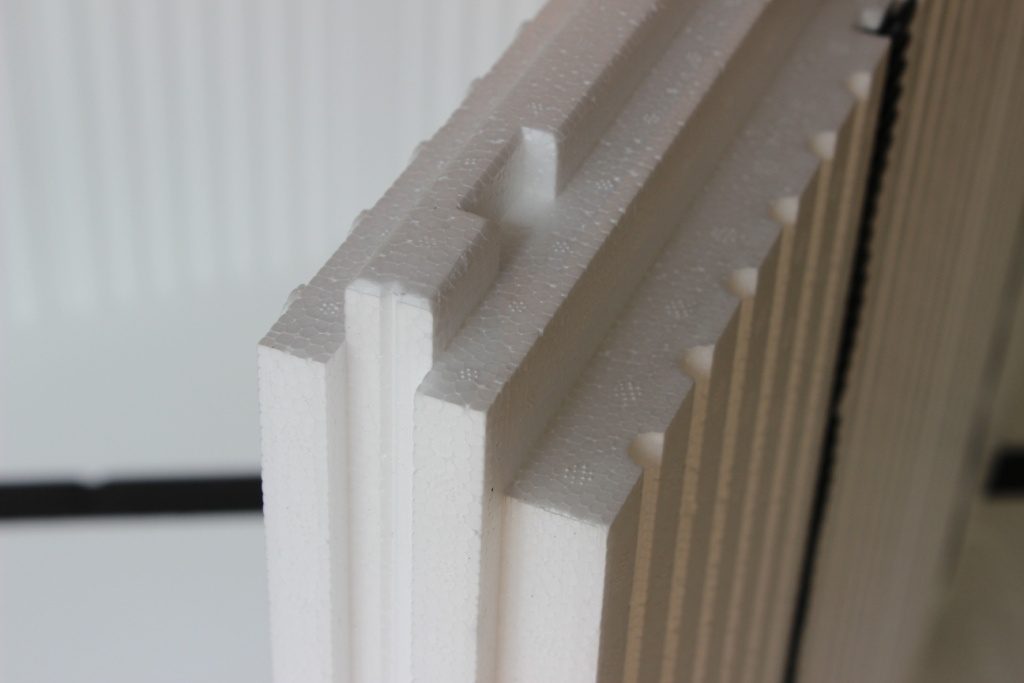

Self-Leveling Tongue-and-Groove Interlocks

Four tightly interlocking edges along each panel form a continuous, self-flashing seal. Unlike traditional flashing tapes, the interlock create a resilient seal that will not change shape, dry or crack over time. The interlocks eliminate the potential for mistaken thermal leaks and prevent water from reaching the face. A notched alignment system ensures the panels and studs stay aligned during installation even when cut. Inset lines demarcate the location of wiring chases.

Moisture Control

Built into the back of the EXi panel is a network of shingle-style capillary channels. The channels are specifically-sized cavities that moderate wall pressure so that both interior and exterior wall assemblies can drain and be allowed to remain dry. The EPS foam features a permeability that ensures moisture is not trapped in walls and, with help from the channels, will “breathe” through to be handled by any standard HVAC system.

Electrical Raceways

Electrical raceways run vertically at 16 inches on center and horizontally at 24 inches on center.

This grid provides easy access to pull wiring to any location. Located at code-approved depth, the chases also provide the necessary separation from the drywall face to protect the wiring.

Double Thermal Disconnect

- Uninterrupted continuous insulation (CI)

- InSoFast goes beyond just “CI”. The fastener that attaches the panel is recessed a ½” reducing thermal shorts to near zero.

- Fastening the cladding does not penetrate the water resistant barrier keeping your building secure and dry.

- EXi 2.5 panel continuous insulation is the best choice for continuous-continuous insulation.

|

FP- 2.5 Insulated Flat Panel with Studs |

|

| FP-2.5 Panel Details | dfx – dwg – pdf |

| FP-2.5 zip file | |

| Architectural Submittal | |

| Panel Dimensions | 24in × 48in × 2½in |

| Horizontal Chase |

48in × 1in × ¾in |

|

Vertical Chase |

24in × ¾in × ¾in |

| Drainage Channel | 24in × ¼in × ¼in |

|

Coverage |

8 sq-ft |

|

R-Value ASTM C518 |

R-10.5 |

| Comparable Performance |

2×4 Wall/R-15 Batts |

|

ASTM C578 Type II CAN/ULC S701 Type 2 |

Closed-Cell injection-molded EPS |

|

ASTM C303 Foam Density |

1.35 lbs per cubic foot |

|

ASTM E96 Water Vapor Permeability |

(Class III Vapor Retarder) 3.5perm/in |

|

Maximum Service Temperature (long term) |

167°F = 75 Celsius (°C) |

|

Recessed ½in below Surface |

|

|

Interlocking Edges |

√ |

|

Service Raceways |

√ |

| Cutting Indication Lines |

√ |

|

Designed Ready for Finishing Attachment |

Interior/Exterior |

|

Exterior Rated Moisture Control |

ORSC, Section R703.1.1-approved |

|

Exterior Application |

√ |

|

Interiors Application |

√ |

| Walls | √ |

| Floors | √ |

| Ceilings | √ |

| Commercial | √ |

| Industrial | √ |

| Educational | √ |

| Foundations Walls | √ |

| Shipping Containers | √ |

| Tiny Houses | √ |

| Passive House | √ |

| LEED/Green Build | √ |

| Interiors | √ |

| Exterior | √ |

| NFPA Assemblies | √ |

Estimating and ordering is simple measure the square feet of floor, wall, or ceiling surface that the project requires to complete the job. Divide the total square footage (xx) by 40 sq-ft. this will determine the number of boxes required for your project, (round up to the whole box count). Don’t overestimate.

-

- One (FP-2.5 Insulated Panel = (8 sq-ft)

- One box of FP-2.5 (5 panels 40 sq-ft.)

Estimating Adhesive Quantity

Estimating adhesive has variables beyond our control, the condition of the wall, and how accurate the tradesmen is with a glue gun? The adhesive manufacturer’s technical sheet states, “A 3/8” (9.5 mm) bead extrudes approximately 38 ft. (12 m).“

That is in a perfect world. When PL Premium 3x adhesive is applied a ⅜” bead on the backside of the stud’s ribbed surfaces roughly equates to 7 InSoFast panels or 56 square feet of adhered wall.

The adhesive follows the “Goldie Locks Rule,” too much, too little, and just right. Doing just right you can expect that 1 large 28-fl oz. tube will cover 21 of our studs (3 studs per panel for 7 panels).

Other considerations additional adhesive should be included for securing the panels at openings like windows, doors and corners.

1 large 28-fl oz. / 828 mL tube = 21 (22″ studs) or 7 panels for 56 Square feet of glued InSoFast wall surface.

- We recommend that you estimate approximately 10% waste or

- 1 tubes of the adhesive = 50 Square feet of wall.

To verify that enough adhesive is used, press the panel into place. Pull the panel back and check to see if the adhesive has spread out beyond the full width of the stud. It is normal for the panel to “float out” from the side of the wall when it is accommodating irregularities the adhesive will bridge gaps up to 3/8″. Additional adhesive may be necessary in some areas.

|

LOCTITE® PL PREMIUM® POLYURETHANE CONSTRUCTION ADHESIVE Rough estimate for 28 ounce tubes of adhesive required |

||

| Square Feet | InSoFast Boxes | LOCTITE® PL PREMIUM®3x |

| 800′ | 20 | 16 |

| 1200′ | 30 | 24 |

| 2000′ | 50 | 40 |

| 3600′ | 90 | 72 |

Please read all the current Shipping, Purchasing & Returns *

| Product Code |

Number of Parts |

Box Dimension |

Cubic Feet Per Box |

Weight Per Box |

||

|

Length |

Width |

Height |

||||

|

EXi2.5 |

5 Panels 40 SqFt |

13″ |

25″ |

49″ |

9.22 |

22 Lbs |