Sidewall Inserts

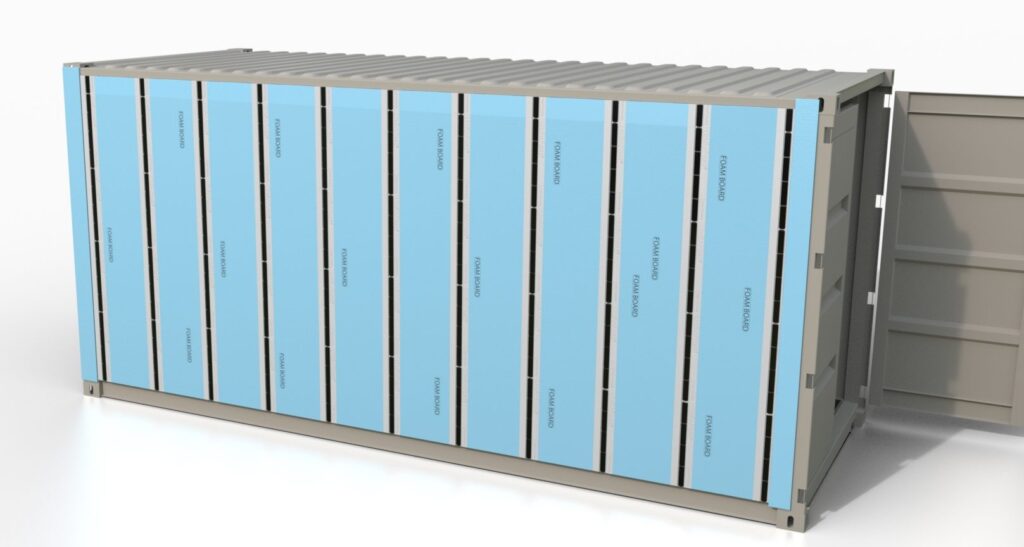

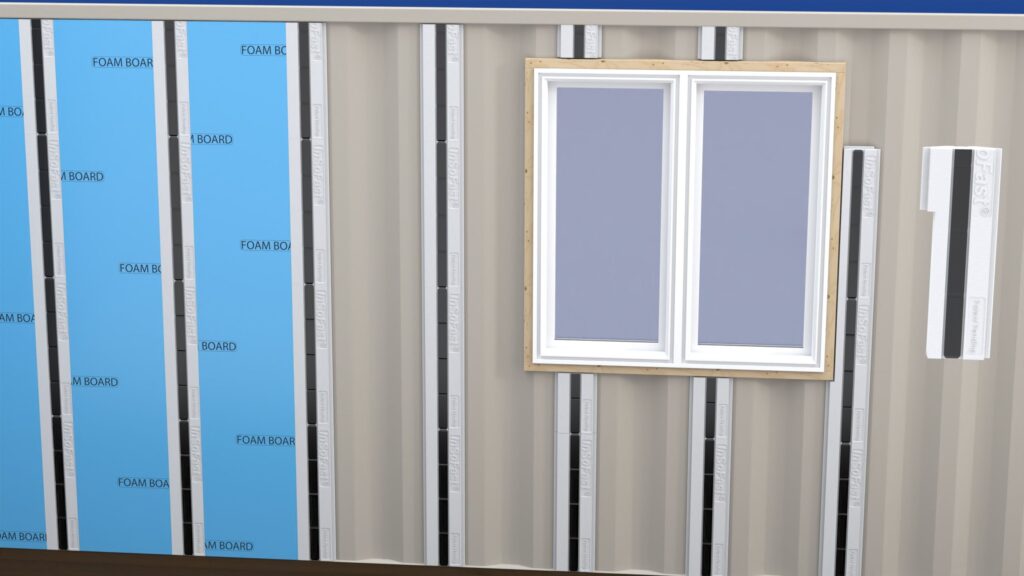

Sidewall Insert with Rigid Sheet Foam

- The sidewall of a shipping container interior applications. If you just need to just insulate a container for storage and covering the insulation for fire safety and protection is not a concern we recommend the (I-SWI) Side Wall Inserts to infill the wall’s corrugated voids to prevent hidden condensation. The flat stock foam panels and inserts is a three-step process insulated first with the (I-SWI) Side Wall Inserts to infill the wall’s corrugated voids preventing hidden condensation. Then locally sourced (48″ x 96″) flat stock sheet insulation are installed over the inserts completing the continuous thermal layer before the traditional interior framing and services can be installed. This is the least expensive method available but increase the labor, material co-ordination and complexity in details.Then install locally sourced board stock insulation over the steel containers exposed metal surfaces.

- Inexpensive method when modifying older containers with dings and dents prevent cold condensation surfaces.

- Method when modifying older containers with dings and dents.

- Industrial fast track application not suitable for habitual spaces, storage only.

- Check with local code restrictions for exposed foam insulation fire requirements.

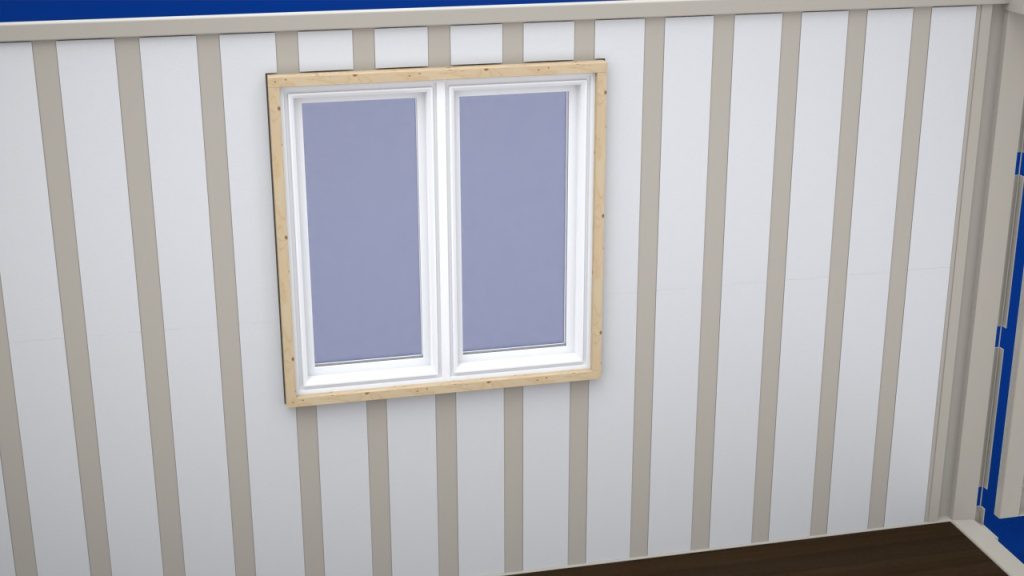

- Traditional framing, wood or steel studs, would need to be installed with drywall and optional additional insulation in order to make the container into a habitable space

Sidewall Inserts:

- (I-SWI Side Wall Inserts) = 30 pieces 48 inches long covering 120 lineal feet of corrugation in-fill or (15) 8′ tall sections

Products Required

I-SWI Side Wall Inserts

Side Wall Inserts – One box of Side Wall Inserts covers 112 Lineal feet of corrugation.

| Dimensioned to fit | 48in x 7 3/4in x 1 1/4 in |

| Coverage | 2.5 sq-ft |

| R-Value ASTM C518 | R-5.3 |

| Closed-Cell, injection-molded EPS | ASTM C578 Type II |

| Canadian Standards | CAN/ULC S701 Type 2 |

| Foam Density | 1.00 lbs per cubic foot |

Installing Sidewall Inserts into a Container

The long sidewalls of the shipping container insulated with Sidewall Inserts.

The long sidewalls of the shipping container is a three-step process using Sidewall Inserts, locally sourced flat stock sheet foam, and traditional framing systems.

Place a bead of adhesive in an “S” pattern down the center of the backside of the sidewall insert. Set the inserts into the lower half of the sidewall corrugations. Once in place seal the top of the insert with a bead of spray foam. Continue to cut, fit and glue all the insert onto the sidewall corrugations. Spray foam and seal all your work.

Flat board stock foam and framing by others.

*Locally Sourced Foam Insulation by others:

| Interior sheet foam Insulation required: | 20′ Standard | 20′ High Cube | 40′ Standard | 40′ High Cube |

| Foam Board Insulation by others: | 3/4″ x 4′ x 8′ | 3/4″ x 4′ x 8′ | 3/4″ x 4′ x 8′ | 3/4″ x 4′ x 8′ |

| Total square feet w/o swing doors | 472 | 520 | 950 | 1016 |

| Total 4’x8′ sheet foam panels | 15 | 17 | 30 | 32 |

CX44 Shaped Panels

Exterior Installation of CX44 Panels

The InSoFast CX Container Panel is designed for the side walls of most shipping containers. The CX panels are set up for an 11″ repeating pattern of the corrugation and the panel size is 44″ x 24″. They are installed horizontally with the studs running vertically. Lay out the first row of CX panels to determine the fit to the container. Variations in the corrugations may require the panels to be trimmed or spaced out slightly. Leave a 1/4″ gap to allow for spray foam sealant.

Before You Glue

Dry fit and adjust your panels to fit. Use a razor blade knife to fit around cargo hooks, dents, weld seams or other protrusions.

Start by gluing the bottom rail panel foam support that was cut and fitted in the insulating the bottom rail. Apply glue in a 3/8″ bead using an “S” pattern.

Place a 3/8″ bead of adhesive on the stud on the exposed dove tailed ribs on the backside of the CX44 panel.

Add Extra Adhesive Around Openings

Since there is no stud at the cut ends of the panels, an additional bead of PL Premium 3x is applied at the start and end of each wall.

Use spray foam to air seal around the openings

Special detailing for the End Wall and Swing Door Frame

The CX44 panel will not work for the end wall and door frame without modification. Here we used the UX2.0 panel to handle the flat surface areas. Additionally the horizontal studs work well for the finish trim and outside corner treatments.

Here we glued the studs and all the outside edges so the panel so ti is solidly attached to the corner.

Secure and brace the panels until the adhesive sets.

Also see Pages; Insulating the bottom rail

Flat Panel & Insert Application

Follow the same instructions as the Interior Sidewall – Flat Panel and Insert Installation

LowPro Exterior Installation

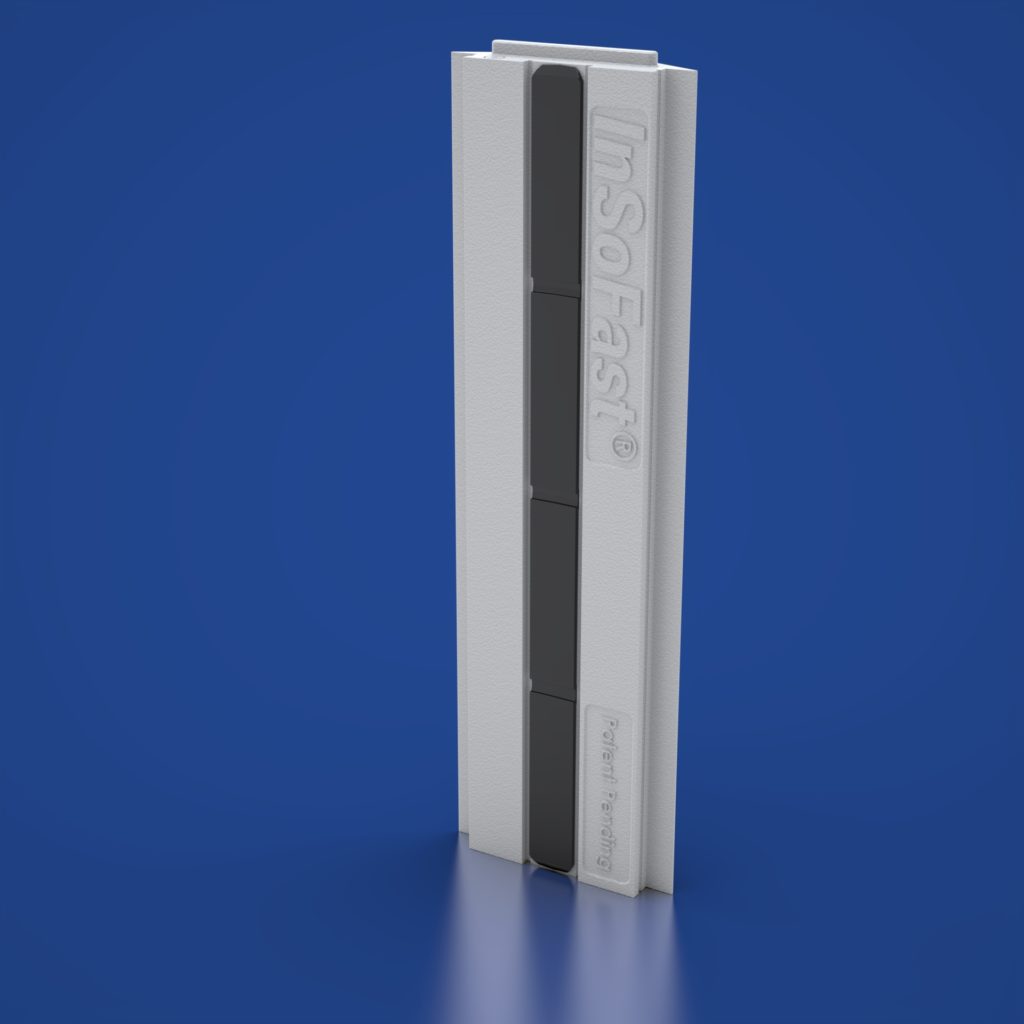

LowPro insulated studs are hybrid engineered solution for insulating containers. It is versatile and can be used for interior or exterior applications. The CX-LP studs are ideally suited for intermodal container conversions and is suited for industrial applications where thin wall insulation and framing is the primary concern. If you are (not planning to embed) electric services like wiring in the wall, or if you are planning surface mounted conduit.

Why you would use LowPro Insulated Studs

LowPro insulated studs are hybrid engineered solution for insulating containers. It is versatile and can be used for interior or exterior applications. One of the many benefits to the stud, it is smaller than the panels making them easier to handle and modify to accommodate working around dings and dents of older containers. The insulated stud eliminates framing cold spots and fastener condensation when insulating a container.

The CX-LP is a hybrid method for insulating a shipping container addresses limited rural delivery and overseas freight charges. CX-LP insulated stud method utilizes foam insulation that you source locally. Flat foam board purchased locally reduce bulk shipment costs.

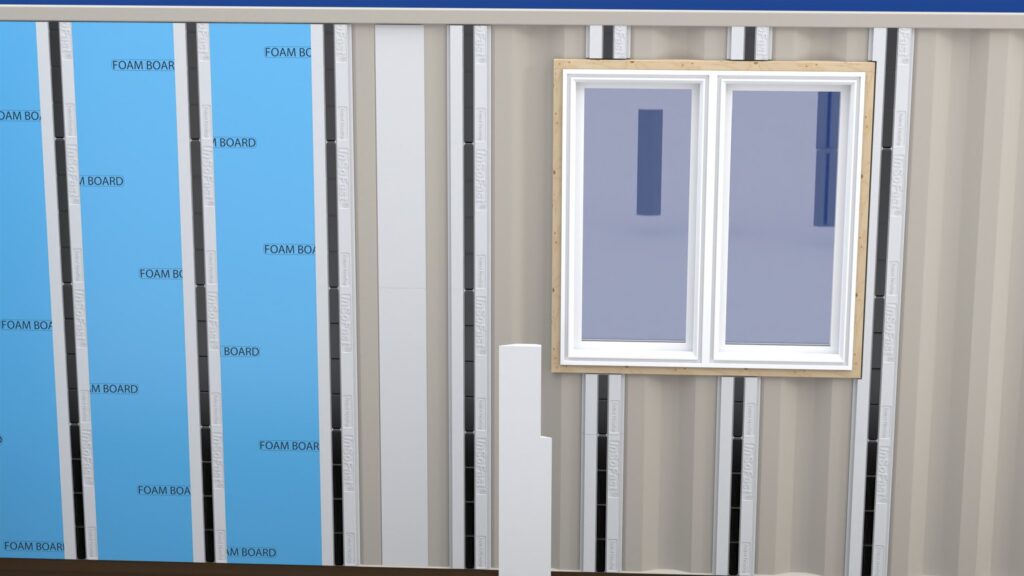

LowPro Insulated Studs Exterior Application

CX LowPro Insulated Studs Exterior application.

LowPro Studs for dented Containers

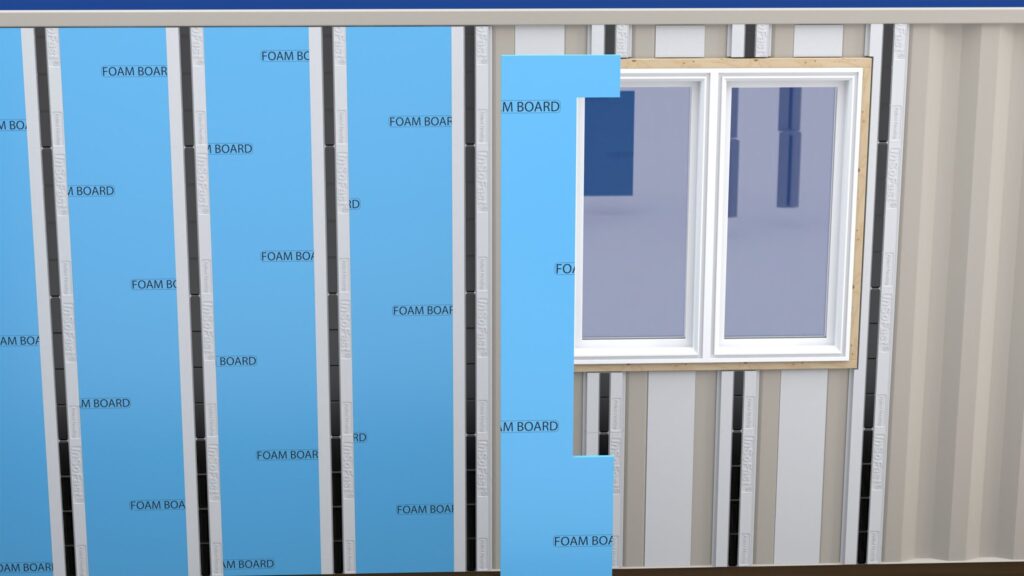

The long sidewalls of the shipping container using the LowPro Stud is a three step process and is insulated with Sidewall Inserts and locally sourced 3/4″ thick sheet foam insulation.The adhesive applied CX-LP eliminates the hundreds of holes associated with shipping container or sea can modifications. The CX LowPro stud is part of a assembly to work with the Sidewalls Inserts. The corrugation infills are typically placed on either 11 – 22 inches on center in an alternating pattern with the (SWI) side wall inserts. The CX-LP insulated infill framing is ideally suited for container conversions in commercial, residential, industrial, interior or exterior applications where thin wall insulation and framing is the primary concern. LowPro used in this configuration with 1/2″ thick drywall only 1 1/4″ of interior space is lost.

Cutting material to fit

It is highly recommended that the 3 components be install at the same time. Once install tamp the panels with a straight edge like a 2×4 lumber to make sure that the wall is level and flat.

Installing the LowPro Insulated Studs

Install the LowPro Insulated StudsApply a 3/8″ bead of Loctite PL Premium 3x construction adhesive horizontally across the top then directly over the ribbed surface of the backside of the stud to form “T” pattern.

The LowPro studs can be cut to fit using regular wood working tools or razor knives. Remember to cut and modify the studs before you glue them.

Installing the sidewall inserts

Place a bead of adhesive in an “S” pattern down the center of the backside of the sidewall insert. Set the inserts into the lower half of the sidewall corrugations. Continue to cut, fit and glue all the insert onto the sidewall corrugations. Spray foam and seal all your work.

Installing the the locally sourced 3/4″ sheet insulation

Install the the locally sourced 3/4″ sheet insulation.

When the LowPro Studs are installed in an alternating pattern of 22″ on center, the sheet foam is cut from a 48″ x 96″ (3/4″) into 16″ wide panels.

Insert 16” sheet foam between the LowPro Inserts. |  Use 5” wide sheet foam when LowPro is installed in every corrugation |

Optionally when the LowPro Studs are placed in an alternating pattern of 11″ on center, the sheet foam is cut from a 48″ x 96″ (3/4″) into 5″ wide panels.

It is highly recommended that the 3 components be install at the same time. Once install tamp the panels with a straight edge like a 2×4 lumber to make sure that the wall is level and flat.

Installing infill insulation in the corner

The outside corner can be filled with 1/2″ thick board stock insulation from a local lumber supplier.

Products Required

| CX-LP LowPro Insulated Stud | Side Wall Inserts | |

| CX LowPro-Side Wall Architectural Details | dwgdxfpdf | Dimensioned to fit |

| Dimensions | 7 1/2in × 24in × 2in | 48in x 7 3/4in x 1 1/4 in |

| Coverage | 2.5 sq-ft | 2.5 sq-ft |

| R-Value ASTM C518 | R-8.5 | R-5.3 |

| Closed-Cell, injection-molded EPS | ASTM C578 Type II | ASTM C578 Type II |

| Canadian Standards | CAN/ULC S701 Type 2 | CAN/ULC S701 Type 2 |

| Foam Density | 1.35 lbs per cubic foot | 1.35 lbs per cubic foot |

| Polypropylene Studs | Surface | N/A |

| Ready for Finishes | √ | √ |

| Interior | √ | √ |

| Exterior | √ | √ |

- One box of the CX-LP 46 Insulated studs will do 92 lineal feet of framing.

- One 20′ container side wall would need 44 pcs, of CX LowPros insulated studs and 20 pcs. of the Side Wall Inserts to do one side.

- One box of Side Wall Inserts has 30 pcs. that are 48 inches long or will cover 112 Lineal feet of corrugation in-fill.

- One box of the CX-LP 46 Insulated studs will do 92 lineal feet of framing.

The high-strength co-polymer plastic studs on 11 or 22-inches centers provide a positive attachment stud for finishing the container. The ribbed dovetails surface provides for adhesive applications against the metal surfaces.

Panels you would need for a complete insulated LowPro Container

| Complete Interior Insulation for a Container; | 20′ Standard | 20′ High Cube | 40′ Standard | 40′ High Cube |

| LowPro Insulated Studs/Inserts Sidewall | Sidewall | Sidewall | Sidewall | Sidewall |

| CX-LP 46 LowPro Insulated Stud | 2 | 2 | 4 | 4 |

| CX-LP 15 LowPro Insulated Stud | 1 | 1 | 0 | 1 |

| Sidewall Inserts: | 2 | 2 | 4 | 4 |

| Box Total: | 5 | 5 | 8 | 9 |

| Endwall (Container) LowPro-Bundle | Endwall | Endwall | Endwall | Endwall |

| Endwall LowPro-Kit | 1 | 1 | 1 | 1 |

| Ceiling 2.0 Flat Panel-Bundle | Ceiling | Ceiling | Ceiling | Ceiling |

| 2.0 Flat Panel (UX) | 4 | 4 | 8 | 8 |

| Inserts: Ceilings | 1 | 1 | 2 | 2 |

| Box Total: | 5 | 5 | 10 | 10 |

| Door 2.5 Flat Panel-Bundle (2) Doors | Door | Door | Door | Door |

| 2.5 Flat Panel (EXe) | 2 | 2 | 2 | 2 |

| Floor 2.0 Flat Panel-Bundle | Floor | Floor | Floor | Floor |

| 2.0 Flat Panel (UX) | 4 | 4 | 8 | 9 |

| Total Box Count: | 17 | 17 | 29 | 31 |

| Foam Board Insulation by others: | 3/4″ x 4′ x 8′ | 3/4″ x 4′ x 8′ | 3/4″ x 4′ x 8′ | 3/4″ x 4′ x 8′ |

| Sidewall | 14.67 | 16.25 | 29.67 | 31.75 |

| Total 4×8 Panel Count | 15 | 17 | 30 | 32 |