First InSoFast EXi 2.5, Moby Arena Colorado

| Install Guide | Ordering Guide | Contact/Quote |

InSoFast EX 2.5™ is an R-10 continuous insulation (CI) weather screen assembly designed for exterior walls. It is part of a complete rain screen solution that maximizes energy efficiency coupled with advanced moisture management properties.

The panel’s rigid insulation and non-ferrous studs are integrated in a unique co-molding process that ensures strong wind load resistance for cladding attachment without sacrificing the thermal barrier. Attachment fasteners are isolated in a non-conductive medium with a ½” of thermal airspace. Engineered drainage channels on both faces of the panel optimize performance of the rain screen by allowing multi-directional air flow.

This all-in-one, patented panel can be used to meet and/or exceed ASHRAE 90.1 requirements while saving time and money by reducing labor and in-field assembly costs. Exterior finishing options can include thin brick, metal panels, tile, cultured stone, stucco, and the popular cement board siding to name a few. All finishes mount to the same CI-System so that one building can have several different looks without disrupting the rain screen or the primary building envelope.

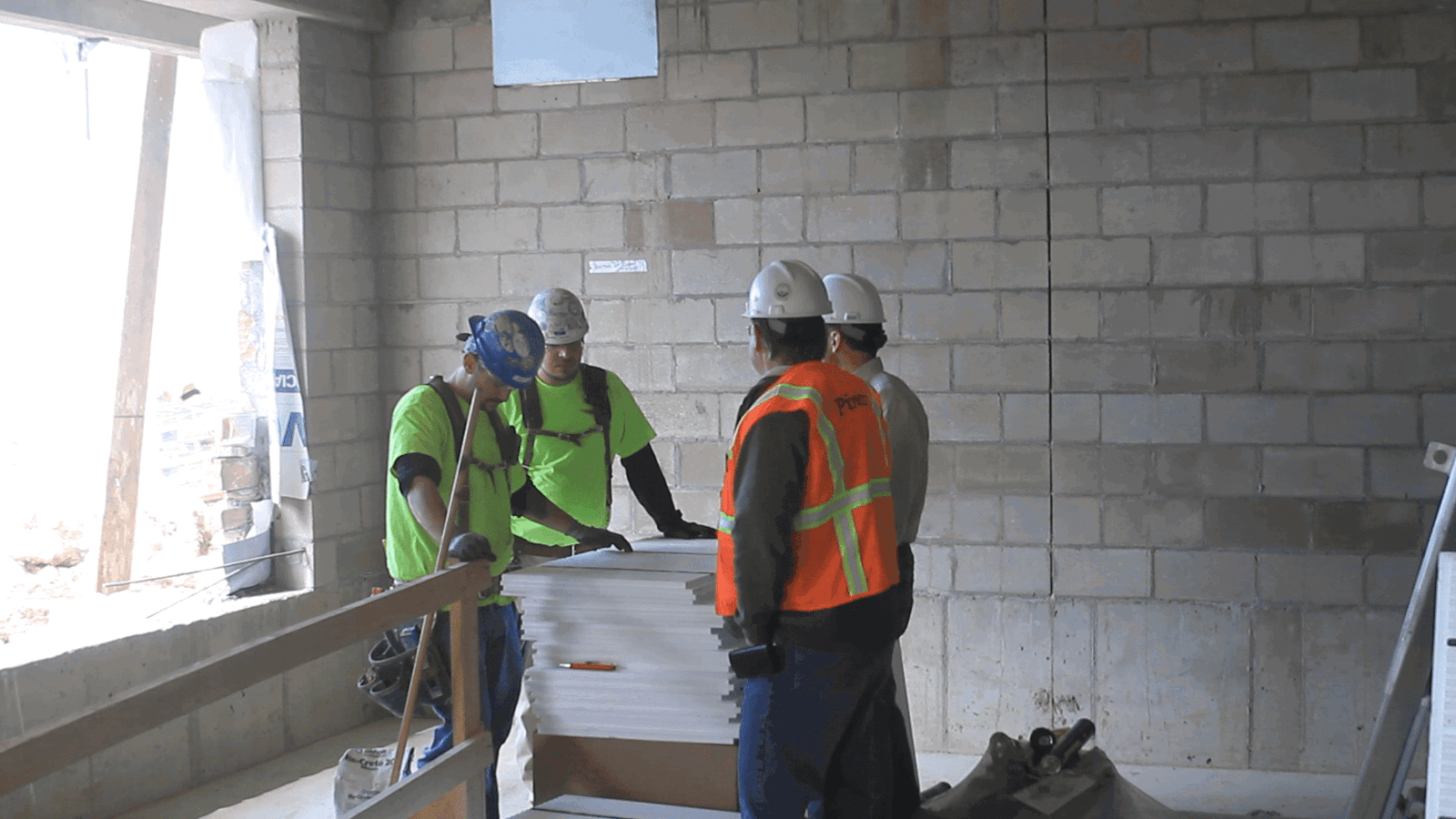

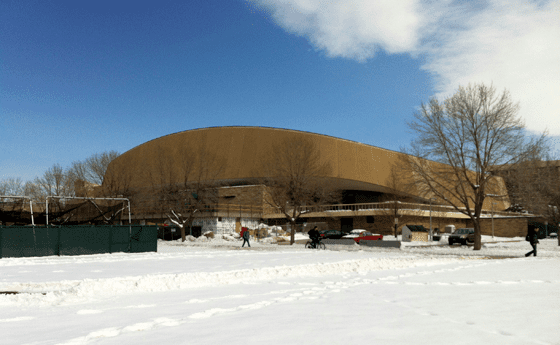

It was a cold weekend in April. A fresh foot of snow packed in the construction site at the Moby Arena. Outside, full pallets appeared like igloos on the landscape. Inside, workers wore gloves and long sleeves beneath their Hi-Vis jackets. They placed tubes of adhesives in front of a gas furnace hoping the heat would soften them. With the snowy Rockies rising in the background, the scene in Fort Collins gave justification to the regional energy codes.

Not long before, architect Mick Aller was seeking a solution for those exact codes. When he and his partners at Aller, Lingle, Massey were charged with designing the 8,000 sq.ft. state-of-the-art training facility at Colorado State University, he went in search of the right materials for the job. In order to address the energy requirements, he needed a continuous insulation that could be mounted to a load-bearing masonry wall. For Colorado, it had to be R13 insulation.

As an award-winning architect, Mick is always on the lookout for new, innovative products that meet both the constantly changing energy codes and simplify the construction process. He says he stumbled across InSoFast while perusing Popular Science magazine. It seemingly answered all his needs: a continuous insulation, built-in studs, electrical chaseways, and moisture control channels.

Unlike materials such as z-furring, the studs would not conduct heat or cold. It would take up half as much space as something like batt insulation. The electrical channels were at code depth meaning they didn’t need to run conduit. And for the training facility that was soon to house a pool, the moisture control channels ensured that mold and mildew wouldn’t be a problem in the future. In fact, at the time Mick called for a sample, the panel was missing only one thing: R13 insulation.

That’s where the InSoFast EX 2.5™ came into the picture. A new panel with embedded studs and an extra half inch of insulation. When combined with the rest of the wall assembly, the EX panel allowed Mick to achieve his goal of R13 insulation.

Design : Aller, Lingle, Massey Architects P.C.

Construction : Pinkard Construction

Supply : Building Specialties