Part One New Home from Old Containers

So you are either interested in building a container home yourself, or you are just curious about what the Ritter-Lopatowski’s are up to these days. Long story short, we are finally and officially building our home out of shipping containers. After first coming up with the idea seven years ago, we are very excited to share with the world the process that we’ve gone through to get where we are now.

Part One

January 26,2017

First and foremost we share this story, even though we are “In-So-Fast,” there is a lot of preparation and planning that goes into building a code compliant shipping container project. It is best to talk to and consult with a design professional before you invest into any major construction project. This story goes back a few years, so we compiled a timeline story of one family’s experience building a container home. We got a call from Jason who was following up on an email he sent about a particularly interesting project in the Pacific Northwest.

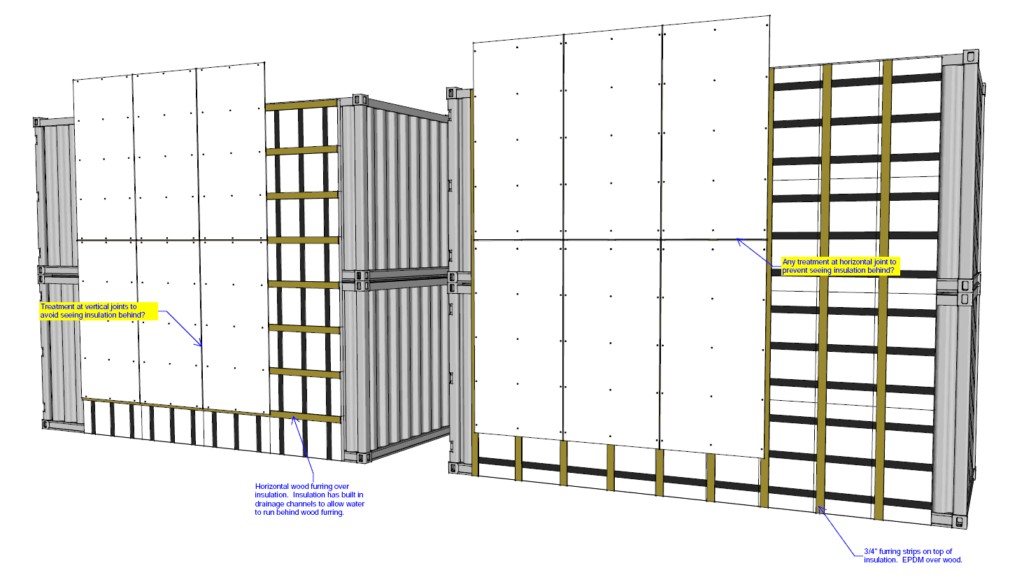

Jason wrote us and asked, “I will be installing a high density fiber cement siding that weighs 3 psf (Cembrit Raw) and I wanted to make sure that your product, adhered only with adhesive, no fasteners through the container wall, will still work? I have attached a sketch showing 2 alternative installation methods. The 16” o.c. spacing of your plastic ribs don’t land exactly where needed. CemBrit, the panel manufacturer requires the vertical furring strips in order to allow the heat behind the panels to escape or a true ventilated rainscreen application.”

We directed, and developed this page to help answer Jason’s questions.

Insulated Studs

We understand the initial concerns people have in learning that our panels’ structural stud framing is often hidden…and that it’s designed to be glued, screwed, or nailed to almost any surface. It’s no small matter to perfect the multiple engineered features that make our panels so dependable, including the stud load capacity.

The InSoFast panel studs provide a simplified approach to wall assembly. The InSoFast stud are injection-molded high-strength recycled polypropylene plastic. Next, a special co-molding process expands the foam insulation around the studs forming one solid panel. The studs provide a structural attachment point to the substrate and for the specified finishes.

February 1, 2018

Jason wrote, “Thanks for the call yesterday. My house is still moving along slowly. Trying to get a foundation bid in place and then off to permit.

I will be sending you some plans in the near future to see if you can give me a take off on the number of panels I need. I have swapped out my current details with the new CX Container panels you emailed me about. I am using these on the interior and exterior of the exterior walls for a great insulated system.

One question for these new panels: Originally I was planning on installing the 2.5 panel so your furring was horizontal in order to add a separate layer of furring strips vertically for my siding product. These siding panels are a rain screen system and need ¾” air space behind them. With these new CX panels, I can only install them one way which puts your integrated furring strips vertically. Will I need to simply add horizontal strips and then a layer of new vertical to get I need?”

Board and Batten Siding

InSoFast’s use of board and batten siding demonstrates one of the many finishing choices you have when you insulate a shipping container with InSoFast. Jason wondered if this application would work with the (Cembrit Raw) rainscreen. It is visually clean and crisp and will have a timeless look and will weather well in the Pacific Northwest.

April 18, 2019

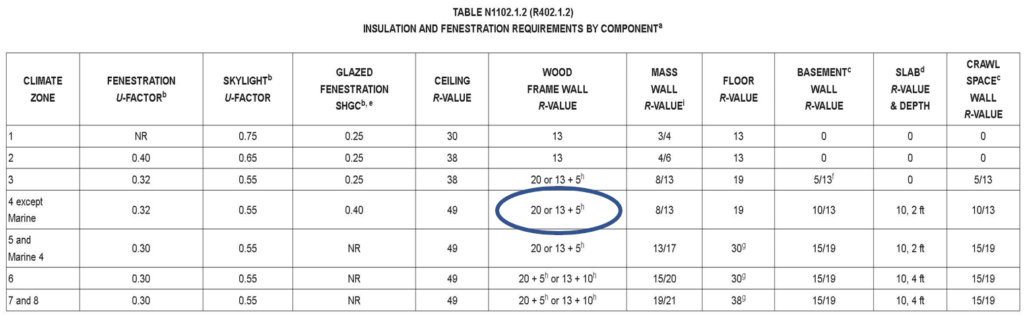

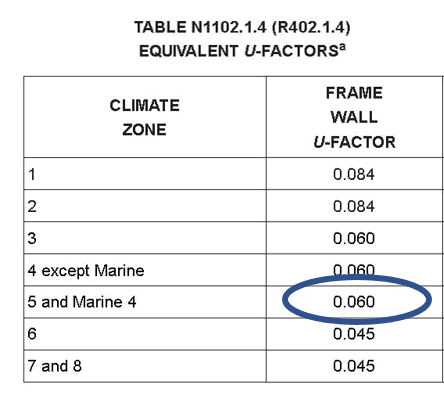

Jason wrote, “Hello InSoFast!. It has been a while; hope all is well. My Container house project is still crawling along. I had to find a new contractor as my last one dropped out. I see that you now have the container insulation panel. This is great news. I am still planning on using your insulation for all my interior and exterior needs on my house. With this new formed container panel, (CX44) what would my R-value be if used on both the interior and exterior of the container walls (sandwiching the metal between foam)? If I use this panel on the exterior too, can I assume that it will still allow me to use wood furring strips in order to install a rainscreen system?

I will be working on a SF number to figure how much insulation panel I need. In the meantime please let me know what the insulation value is. 2018 IRC requirements are below. I am in Marine 4 so I need R20 or a U value of .060. Secondly, do you know if I need to install a WRB on the container exterior before adding the insulation? It seems that the container would act as the WRB, but do I need to worry about condensation under the panels?

Or I can use the U-Value table which equates to an R-Value assembly of 16.67.”

April 18, 2019

InSoFast may be finally getting ahead of Jason’s needs. Here is a chart that should help you reach your R or U-values you need to achieve. Additionally, our newest product, the LowPro Insulated Stud (available 6-1-2019), is better rainscreen design for your application. The LowPro will give you more attachment options for the exterior application.

Interior Space vs R-Value

InSoFast lets you balance high performance wall insulation against your valuable interior LIVING space.

Download Chart as a PDF for code submittal. Shipping Container R-Value vs Space Comparison InSoFast

Jason does not need a weather resistant barrier (WRB)…the container is a sea worthy container and one of the best WRB. The insulation (acting like a WRB) will stabilize the steel’s thermal drift sandwiched in-between the two layers of insulation.

April 23, 2019

Jason wrote:

“InSoFast,

What a fantastic installation packet. That gave me exactly what I needed. I will take a look at the LowPro stud and see how that will work with my rainscreen system. I think I will still need to add horizontals in order to get my fasteners locations for my panels aligned.

Thanks, Jason”

August 14, 2020

Jason wrote:

“InSoFast,

I just got an email about the PL Premium glue in the 28oz tubes. Do you know of any adhesive that are available in a sausage style that work as well as PL Premium? I am trying to wrap my head round how many tubes I’ll be throwing away with my project. I have seen lots of sausage sealants on my jobs but not this PL Premium specifically.

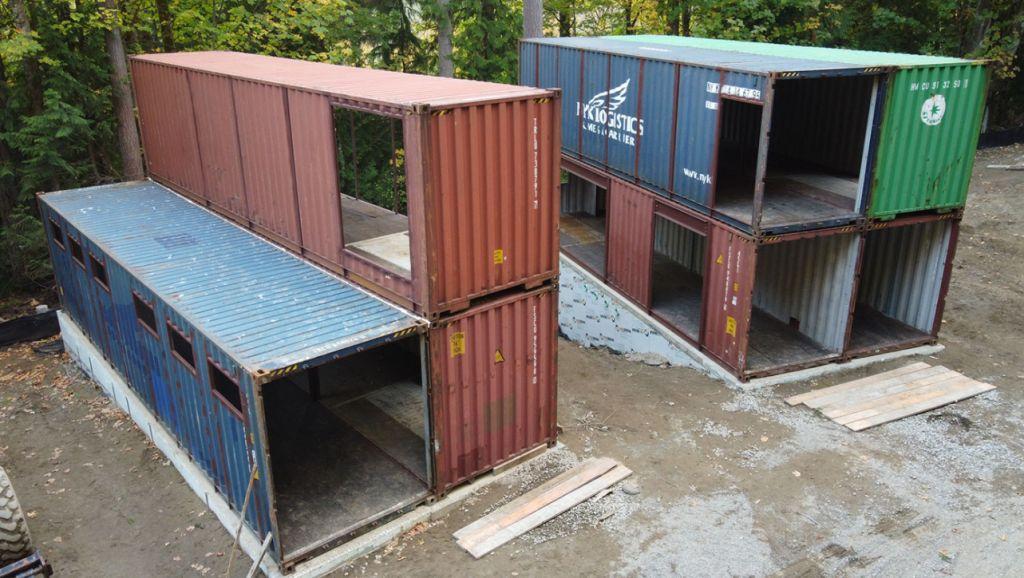

Also, I’ll be ordering InSoFast pretty soon for my container house. Using (7) 40’ HC so you can understand my concern about waste. My footings are getting rebar now and my containers are getting the steel ready to cut and reinforce openings.

Finally, check out our container house website if you are curious about this project!”

August 14, 2020

InSoFast’s responds to Jason:

“Loved your website.”

October 22, 2020

Jason wrote:

“InSoFast,

I wanted to circle back on this. I am having all of my containers delivered Monday where I can finally confirm all corrugation patterns and make sure they are all standard for your insulation. Based on my quick site visits to the container yard, they are all the same. After my wife and I had a chance to walk through some of them, we are wanting to expose more of the interior side of the container walls in order to see the steel hooks, and brackets that you see in the corners. Those kind of details are a really unique aspect that “normal” homes just don’t have. Plus we can tie off hammocks in my kids room which will be quite unique.

So I am thinking that I will only insulate the outside but would still love to have a zoom call or phone call to discuss as you mention below. You have far more experience in this and will have some great thoughts. We have our containers stacked on site now. Super exciting to see it come together. I could begin installing insulation as soon as it can be delivered.”

Next Part Two:

The InSoFast was delivered “fast” and the installation was easy?

These panels’ dimensions are 24x48x2.5 inches, and when they’re put together into a solid wall of insulation, they provide a balance of strong energy protection and protection from the elements. The closed-cell EPS foam is non-porous, so the system can serve as a reliable weather resistant barrier that repels water rather than absorb it.

Our products are easily installed with tongue-and-groove notches that connect the panels to one another. A complete system leaves no gaps for thermal bridging, and all you’ll need for the process is a utility knife, a saw, a nail gun or drill, and canned spray foam insulation. The process is intuitive and a seasoned construction professional or DIY weekend warrior can both expect superior results.

The best insulation for your container home is InSoFast Container Quote. Reach out by calling (888) 396-9677 or by contacting us online if you need assistance with orders, installation, measurements, etc.